Metal Domes or No Metal Domes: Which Membrane Switch Setup is Superior?

Metal Domes vs. No Metal Domes: Key Differences in Membrane Switches

Tactile Feedback and Actuation Mechanisms

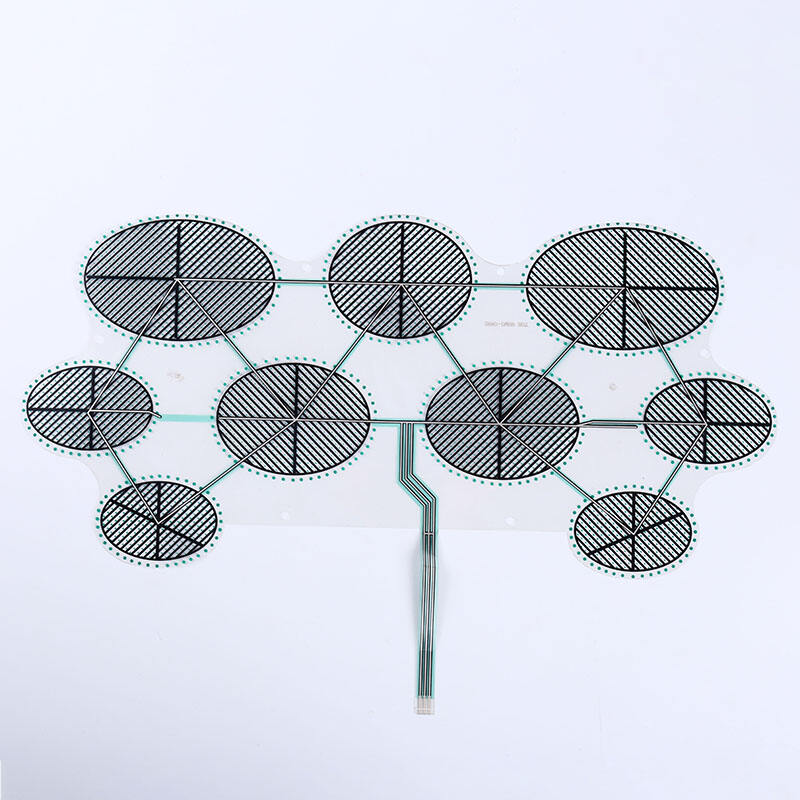

Metal domes significantly enhance tactile feedback in membrane switches, boosting user satisfaction by providing a noticeable "click" upon actuation. This feedback is crucial for applications like medical devices and industrial controls, where precision and error reduction are vital. In terms of actuation mechanisms, membrane switches can be mechanical or capacitive. Mechanical switches rely heavily on components like metal domes for their tactile response, while capacitive types measure the change in capacitance caused by a user's touch. A user experience survey might reveal that a majority of users prefer the reliability of tactile feedback due to the clear actuation confirmation it provides, potentially reducing input errors and enhancing efficiency.

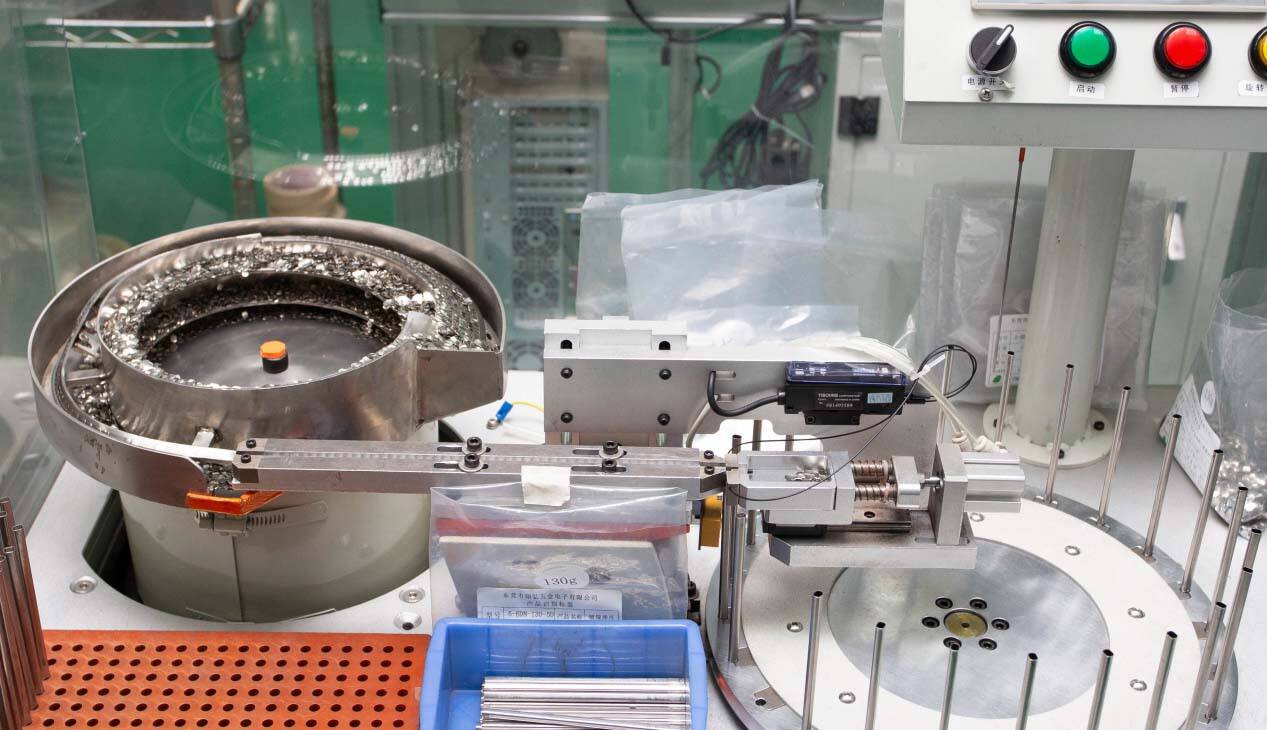

Durability and Lifespan Comparisons

Metal domes are generally more durable and resistant to wear than their non-metal counterparts, translating into a longer lifespan for membrane switches featuring these components. The inherent material properties provide resilience against harsh environments, making them ideal for use in challenging settings. Testing standards such as MIL-STD and IEC are critical in assessing durability, as they simulate various environmental conditions to evaluate product performance over time. Manufacturers often publish data that emphasize these durability differences; for instance, rigorous tests may show that metal dome switches can withstand millions of actuations, surpassing non-metal types by a significant margin. This longevity can be particularly beneficial in industries requiring reliability and minimal downtime.

Cost and Maintenance Considerations

When evaluating the costs associated with metal dome versus non-metal dome switches, it's essential to consider both initial and long-term expenses. While metal dome switches may have higher upfront manufacturing costs, their extended lifespan and low maintenance needs can lead to reduced long-term expenditures. Applications in industries that demand durability and reliability, such as aviation and heavy machinery, might justify these higher initial investments due to the potential savings on replacements and maintenance. Industry reports often underscore this cost-effectiveness over time, illustrating how durable switches can ultimately provide a better return on investment in comparison to cheaper, less durable options.

Tactile Feedback and User Experience

Advantages of Metal Dome Tactility

Metal dome tactility enhances user interaction and significantly reduces input errors, making it an ideal choice for applications requiring precision. Studies on user testing have shown that the tactile sensation of metal domes simplifies complex operations by reducing the cognitive load, particularly in high-demand environments such as medical and industrial settings. This tactile feedback acts as a psychological booster, instilling confidence in users operating devices. Experts in usability emphasize the advantageous impact of metal dome tactility on cognitive processes, ensuring smooth and accurate user experiences, and facilitating critical tasks with efficiency.

When Non-Tactile Designs Excel

Non-tactile designs are often preferred in scenarios that demand aesthetic minimalism and modern visual interactions over physical feedback. These designs excel in environments where user feedback is primarily visual, such as touch screens in consumer electronics. The lack of metal domes supports easy maintenance and surface cleanliness, crucial in hygienic-sensitive areas like medical settings. Design trends increasingly value sleek surfaces, aligning with the preferences of industries that prioritize an uncluttered and sophisticated look. Insights from these trends show a growing demand for non-tactile designs, particularly in sectors emphasizing hygiene and streamlined aesthetics.

Hybrid Solutions for Balanced Performance

Hybrid membrane switch designs offer an optimal blend of tactile and non-tactile features, meeting diverse user needs and preferences. These solutions are particularly relevant in consumer electronics, where a balance between aesthetic appeal and functional usability is crucial. Hybrid configurations allow devices to cater to both tactile and visual interaction preferences, enhancing user satisfaction. Market analysis reveals a positive growth trend in hybrid solutions, driven by their capability to deliver balanced performance and adaptability in various applications. As industries evolve, hybrid designs increasingly meet the demand for sophisticated yet user-friendly interfaces, showing promising adoption rates across different market segments.

Durability and Environmental Resistance

Sealing Capabilities in Different Configurations

Sealing technologies are crucial in different membrane switch configurations to ensure device longevity. By using advanced sealing methods, these switches can be protected against various environmental factors like dust, humidity, and temperature fluctuations. This not only extends the life of the device but also enhances consistent performance over time. In medical applications, for example, stringent sealing is required to maintain sterility, preventing contamination that could compromise patient safety. In contrast, industrial settings prioritize robust seals to guard against harsh working conditions and reduce failure rates. Comparing the failure rates due to environmental exposure, it's clear that a carefully implemented sealing strategy significantly enhances the durability and reliability of membrane switches across diverse applications.

Performance in Harsh Conditions

Evaluating membrane switches' performance in harsh conditions is vital, especially in environments with high temperatures, severe cold, and chemical exposure. Performance criteria are often set through rigorous industry testing, simulating real-world challenges to ensure that the switches can withstand such extreme environments. For example, some membrane switch designs undergo tests that mimic industrial sectors' harsh conditions, ensuring their robustness is adequate. Case studies and user testimonials from industries like oil and gas highlight switches that continually perform well, despite regularly facing extreme conditions, thus validating their effectiveness and reliability. This data provides potential buyers confidence in the switches' capabilities to endure and function in demanding settings.

Chemical and Moisture Resistance

Choosing the right materials for membrane switches is crucial to resist chemical exposure and moisture. Proper material selection ensures that the switches can maintain their functionality and appearance without degrading from environmental stresses. Many manufacturers obtain specific certifications that validate the chemical and moisture resistance of their products, which are essential for building trust and ensuring compliance with industry standards. Statistics from testing labs often show that membrane switches offering high resistance can significantly outperform others, providing lasting solutions in environments where chemical contact and moisture are prevalent. These insights are invaluable for potential buyers who require assurance and reliability in their keypad solutions.

Top Membrane Switch Solutions for Industrial and Medical Applications

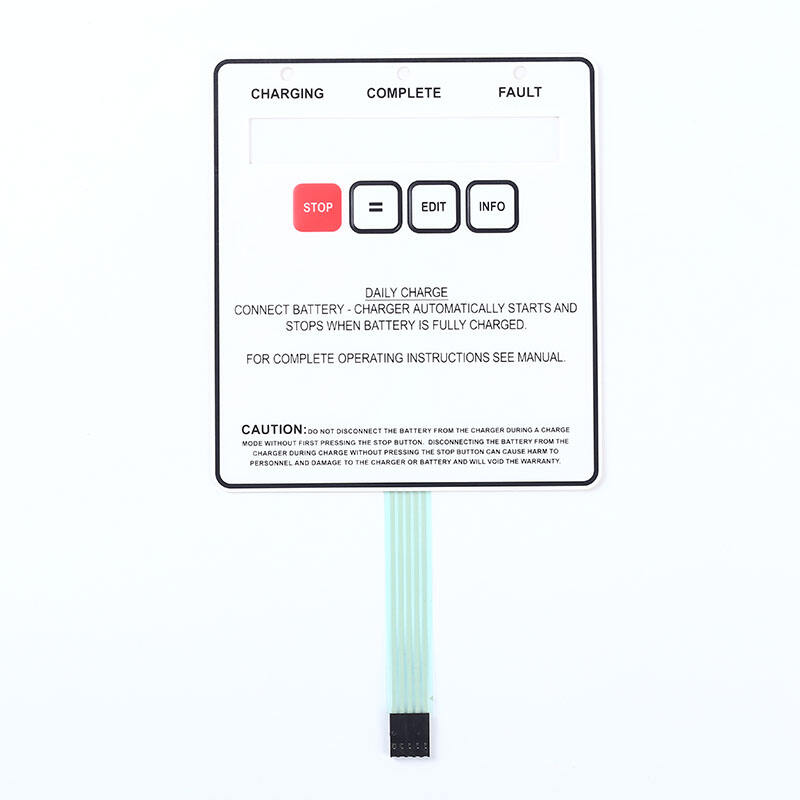

PET Membrane Switch: Lightweight and Flexible

PET membrane switches stand out for their lightweight and flexible properties, making them ideal for portable applications. The use of Polyester film (PET) in these switches enhances device mobility and user comfort. A growing number of industries, including consumer electronics and medical devices, adopt PET due to its adaptability. In fact, sales growth in the PET membrane switch sector has been remarkable, driven by its application in emerging technologies. Industry leaders have echoed similar sentiments, emphasizing the material's role in facilitating slimmer and more adaptable device designs.

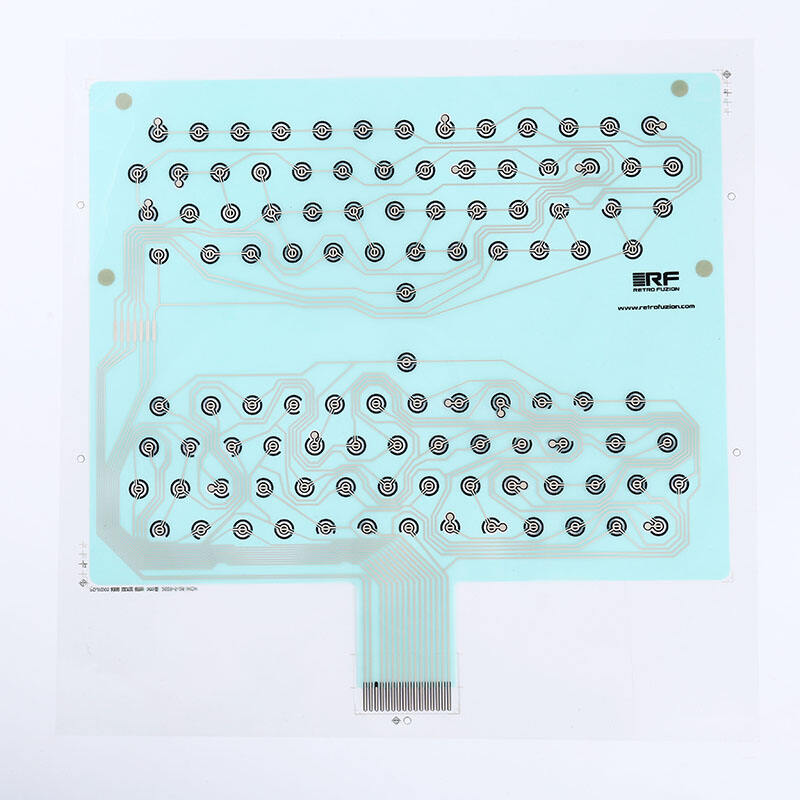

Medical Treatment FPC Membrane Switch: Precision for Healthcare

The Medical Treatment FPC membrane switch is tailored for medical applications, where precision is paramount. Flexible Printed Circuit (FPC) designs allow for enhanced accuracy in controlling medical devices, meeting the stringent standards required in healthcare environments. These switches, regulated by industry standards, guarantee that the control systems operate faultlessly under critical conditions. Real-world case studies highlight their effectiveness, showing improved patient outcomes through precise controls. This precision is vital for applications where even minor inaccuracies can have significant consequences.

Custom Backlit Membrane Switch: Enhanced Visibility

Custom backlit membrane switches provide unparalleled visibility in low-light environments, crucial for user safety and clear interface interaction. These switches not only enhance interface clarity but are versatile in design, allowing for tailored branding and user experiences. Industries like emergency services and nighttime operations benefit greatly from backlit options, ensuring functionality and visibility when it's needed most. The design flexibility offered by these switches can profoundly impact user engagement and brand differentiation.

Membrane Circuit Switch: Reliable Signal Transmission

Membrane circuit switches are essential for reliable signal transmission across a multitude of devices. Improvements in conductivity and design have significantly impacted performance metrics such as response time and efficiency. These advancements have transformed how signals are transmitted, reducing latency and enhancing reliability. Scientific studies illustrate how membrane circuit switches outperform traditional switches, showcasing their superiority in consistent and efficient signal transmission, which is vital for complex applications.

Membrane Circuit Switch (Advanced Model): High-Density Integration

The advanced model of the membrane circuit switch introduces high-density integration, a critical advancement for complex devices. This innovation enables compact and efficient designs, particularly in smartphones and advanced medical devices, where space optimization is crucial. As demand for these integrated solutions grows, market trends show a pronounced uptick in preference for high-density options, driven by their ability to enhance device functionality without compromising on performance.

Choosing the Right Setup for Your Application

Industrial Control Panel Requirements

When selecting membrane switches for industrial control panels, several essential requirements need consideration to ensure compatibility and functionality. Start with a checklist that includes factors such as resistance to environmental factors (like moisture and temperature fluctuations), electrical properties, and panel size. It's vital to acknowledge common challenges during implementation, such as ensuring durability and responsiveness of the switch, and mitigate them by choosing switches designed for industrial environments.

Industry examples can provide insights into successful implementations. For instance, manufacturing facilities often leverage membrane switches tailored for rugged use to withstand the harsh conditions. These switches provide excellent performance and reliability, enhancing operational efficiency. Investing in the right type of membrane switch for industrial applications not only increases durability but also ensures seamless integration with existing systems.

Medical Device Interface Considerations

Medical device interfaces demand careful attention to several critical considerations, particularly in adhering to regulatory compliance and ensuring user-friendly designs. Regulatory guidelines emphasize the need for safety and precision, which is why medical devices often incorporate membrane switch keyboards that offer precise tactile feedback. This detail is crucial for healthcare professionals who rely on reliable performance during critical tasks.

Ergonomics is another crucial factor, as it directly affects user interaction and the comfort level of healthcare workers when operating devices. Standards organizations, such as the International Electrotechnical Commission (IEC), provide valuable guidelines that medical device manufacturers can follow. Compliance with these standards not only safeguards patients but also elevates the device's safety profile, instilling trust among users.

Consumer Electronics Use Cases

The versatility of membrane switches makes them a preferred choice for diverse applications in consumer electronics. From remote controls to modern smart gadgets, these switches offer practicality and style. The market trend shows an increasing consumer preference for sleek, intuitive interfaces, influencing the product development process. Consumers highly value the tactile feedback and aesthetic appeal provided by these switches.

Sales data further supports this trend; there has been significant growth in the adoption of membrane switch interfaces in consumer electronics. Companies are continually innovating to meet this demand, focusing on creating interfaces that not only enhance functionality but also complement the device's overall design. These advancements underscore the pivotal role that membrane switches play in shaping user experiences in the consumer electronics sector.

Hot News

-

Membrane Switch Panel Sample Instructions

2023-12-14

-

Do You Know the Reasons Why Hot Pot Slices Cannot Pop Up When Pressed?

2023-12-14

-

What is a Light Guide? Hongmao Specializes in the Production of Light Guide Sheets, Did You Know?

2023-12-14

-

How Many Rulers Are Needed To Make A Membrane Switch?

2023-12-14

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI