Printed Electronics Are The Name Of The Game In Sensor Design

Used in all kinds of things — smartphones, cars and even medical devices — these high-tech sensors are smaller than a hair, literally. Hongmao is at the vanguard of this revolution, employing advanced technology to produce sensors faster and cheaper than ever.

Re-defining Sensor Production with Printed Electronics

The ways that printed electronics are shaking up the sensor world in a big way is by enabling production to be faster and cheaper. Conventional sensors are usually fabricated by complicated and costly procedures, while printed electronics can be used to form the sensors by a simple print process.

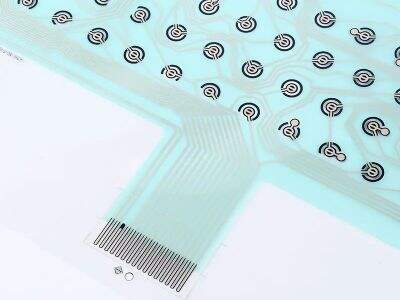

Printed electronics also provide a great deal of freedom in sensor design. Sensors Printed Electronics/Soft Circuit Membrane Switch for custom applications can take a long time and cost more to manufacture using conventional manufacturing process. However, in printed electronics a sensor can very quickly be tailored to fit by literally re-drawing the pattern print design.

Also, with printed electronics sensors can be used in all kinds of waste surfaces and materials. This means they can be easily integrated into ordinary objects, rendering them “smart”, in a manner that allows them to collect data in ways which were not possible before. For instance, sensors can be printed on clothes to check vital statistics or packed in packaging to gauge freshness of a product.

How Printed Electronics is Revolutionizing the World of Sensors

Aside from sensor fabrication, printed electronics are also revolutionizing how sensors are employed in and perceived by assorted industries. The development of sensors embedded in everyday objects is contributing to the advancement of an environment called Internet of Things (IoT), where these devices are connected and cooperate thus allowing for more control and convenience.

In addition, printed electronics is enabling new sensor design possibilities that are not possible or practical to make before. Flexible and stretchable sensors can now exist due to the advent of printed electronics, leading to potential applications in healthcare, robotics and beyond.

Related, there is increased sensor functionality and performance returning through printed electronics. The most recent achievements in materials science and manufacturing methods have enabled to produce sensors that are more miniaturized, sensitive and power efficient than ever before. Doing so enables sensors to acquire more accurate data, longer operating times, under a diversity of environmental conditions.

Printed Electronics for Efficiency in Manufacturing Sensors to the Max!

Hongmao is leading the way in how printed electronics will transform the way sensors are made. Printed electronics is the process of using printing methods to produce electronic devices on different substrates like plastic and paper. This technology provides several benefits such as low cost, scalability, and design flexibility. Hongmao' s printed electronics can bring revolution to the traditional Membrane Switch production process, enabling streamlined production processes and cut in material consumption which are horny for all sensors you need.

One of the main advantages of printed electronics in sensor production is the cheapness that this type of fabrication process provides. When the electronic materials are printed, it is possible to deposit them in a very defined manner; less material gets wasted, and production costs will be lower

Another attractive feature of printed electronics in sensor fabrication is the scalability. Hongmao is also particularly competent in adapting production capacity to supply and demand, increasing or decreasing the number of printing passes as necessary. This flexibility can quickly meet customers' diversification requirements, and make sure that Hongmao will deliver sensors on time. Moreover, the opportunity to instantly prototype sensor ideas with printed electronics allows Hongmao to test new theories and develop innovative products within a shorter timeline than we ever had.

Common Application Challenges in Printed Electronics for Sensors’ Fabrication

Although printed electronics has many advantages in sensor fabrication, there are some prevailing use problems that Hongmao should consider to solve the key issues of the quality and stability printed sensor. One issue shared by both methods is the sensitivity of printed electronic circuitry to environmental conditions, including moisture level and temperature changes. Printed sensors may suffer from performance loss or malfunction upon exposure to extreme conditions due to which they offer inaccurate results.

Additionally, to address another use case shortcoming, in the field of printed electronics for sensor production there is an ongoing drawback when it comes to durability for the sensors printed with inks compared to conventional types. Printed circuit electronic circuits may be subject to wear over time, particularly in high use applications or hostile environments.

Questions to Run Through when Deciding on Printed Electronics for Sensors

9.6Sensor Reliability and Durability The effect of printed electronics on sensor reliability and longevity is another important area to address. Hongmao will need to consider the risks and challenges associated with using printed circuits in sensors, like sensitivity to environmental conditions and fabrication defects, in order for printed sensors to pass stringent quality tests. With extensive reliability testing and reliability analysis,

In addition, Hongmao shall also investigate the scalability and production ready capacity of printed electronics for sensor fabrication. Some of those areas are” “How easily sensor can be produced in the printed form, what kind of volume could we produce them in, and how quickly or expedited would it be to print out a new design for a sensor? Through understanding the scalability of printed electronics and flexibility in production process that printed electronics can offer, Hongmao could improve its manufacturing operational efficiency, reduce time to market and be more flexible to the market. This strategy for producing planning will guarantee Hongmao is capable to respond customer need quickly, and can deliver Touch Membrane Panel with high-quality on time.

printed electronics is transforming sensor fabrication, bringing low-cost and high throughput to production while enabling new classes of sensors. There are widespread usage concerns that you need to solve, for example, the environment friendliness, durability and manufacturing defaults but Hongmao can address these difficulties via stick supervision and quality eligibility test. Through inquiring the advantages, reliability and scaling-up of printed electronics for sensor fabrication,

Table of Contents

- Printed Electronics Are The Name Of The Game In Sensor Design

- Re-defining Sensor Production with Printed Electronics

- How Printed Electronics is Revolutionizing the World of Sensors

- Printed Electronics for Efficiency in Manufacturing Sensors to the Max!

- Common Application Challenges in Printed Electronics for Sensors’ Fabrication

- Questions to Run Through when Deciding on Printed Electronics for Sensors

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI