Nous voulons tous un interrupteur à membrane facile à installer. Voici comment l'obtenir.

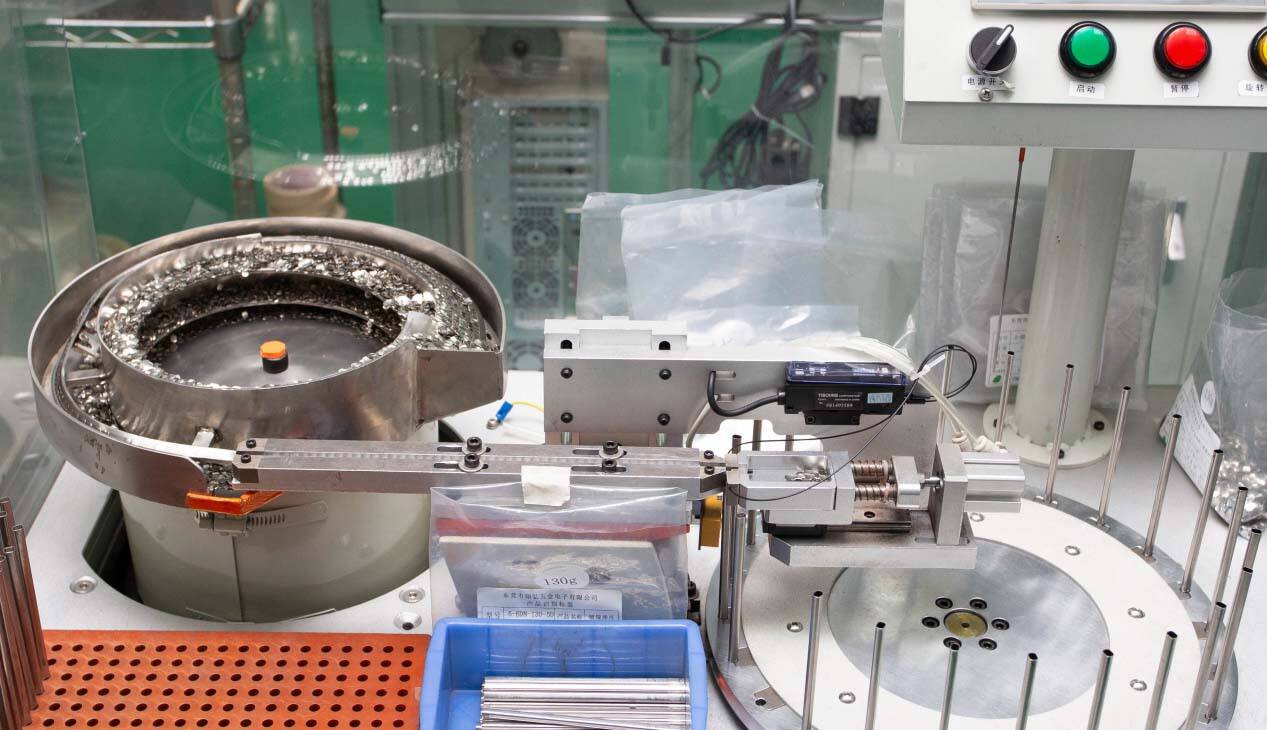

Outils Essentiels pour l'Installation d'un Commutateur à Membrane

Liste de Vérification des Outils Essentiels

Lors de l'installation d'un commutateur à membrane, disposer d'une liste complète des outils essentiels est crucial pour garantir un processus d'installation fluide. Cette liste doit inclure :

- Couteaux de poche : Indispensables pour un découpage précis sans endommager la membrane délicate du clavier ou les matériaux environnants.

- Pince à épiler : Pratiques pour manipuler de petits composants, en assurant un positionnement précis, surtout dans les espaces serrés.

- Matériaux de nettoyage : Des outils comme des chiffons en microfibres et de l'alcool isopropylique sont vitaux pour la préparation des surfaces afin d'éliminer les huiles et d'éviter la contamination des commutateurs à membrane.

- Matériel de mesure : Les règles ou les pieds-toises assurent un alignement et un espacement précis des composants du commutateur.

- Équipement de sécurité : Les gants et les lunettes de protection sont importants pour se protéger contre les vapeurs d'adhésif et les blessures possibles causées par des outils tranchants dans l'environnement d'installation.

Il est essentiel de choisir des outils spécialement conçus pour manipuler des matériaux délicats afin d'éviter tout dommage potentiel. S'assurer que chaque élément de cette liste de contrôle est disponible et en bon état avant de commencer l'installation peut considérablement réduire les erreurs et améliorer l'efficacité de l'installation.

Techniques de préparation de surface

La préparation de la surface joue un rôle pivot dans l'installation réussie des interrupteurs à membrane. Une surface bien préparée assure une adhésion optimale et prolonge la durée de vie de l'interrupteur. Voici quelques techniques clés de préparation :

- Nettoyage : La surface doit être soigneusement nettoyée à l'aide d'alcool isopropylique pour éliminer les huiles, les graisses et les particules de poussière, qui peuvent compromettre les propriétés adhésives du clavier à membrane.

- Texture de Surface : Reconnaître le rôle de la texture de la surface peut être crucial. Une surface lisse améliore souvent l'efficacité de l'adhésif, offrant une meilleure fixation pour les interrupteurs à membrane.

- Techniques d'adhésion comprendre comment les différentes méthodes d'adhésion interagissent avec divers matériaux aide à améliorer les performances et la durabilité de l'interrupteur.

Une préparation correcte de la surface améliore non seulement l'adhérence, mais aussi la fonctionnalité globale de l'interrupteur membrane, garantissant qu'il fonctionne efficacement dans son application souhaitée.

Guide étape par étape pour l'installation de l'interrupteur membrane

Positionnement correct de l'interrupteur

Le positionnement précis de l'interrupteur membrane est fondamental pour éviter les erreurs d'installation et garantir une fonctionnalité appropriée. Un mauvais alignement peut entraîner des problèmes opérationnels, rendant l'interrupteur inefficace. Pour minimiser ces problèmes, l'utilisation de gabarits ou de guides lors de l'installation est fortement recommandée. Ces outils aident à s'assurer que l'interrupteur est parfaitement aligné avec l'espace désigné, réduisant le risque d'erreurs. En utilisant ces méthodes, vous pouvez améliorer à la fois la précision et la fiabilité de votre installation d'interrupteur membrane.

Application de l'adhésif sensible à la pression

Choisir le bon type d'adhésif sensible à la pression est crucial pour l'installation de l'interrupteur membrane, car différents adhésifs répondent à des applications spécifiques. Une application correcte assure une couverture complète et empêche la formation de bulles d'air—un problème courant qui peut compromettre la fiabilité de l'interrupteur. Pour obtenir des résultats optimaux, suivez les meilleures pratiques telles que répandre soigneusement l'adhésif et prêter attention aux éventuels espaces d'air. Comprendre les temps et conditions de durcissement nécessaires pour une adhérence optimale est également essentiel, car ils peuvent influencer considérablement le succès du processus de montage.

Fixation des câbles flexibles et connecteurs

S'assurer que les câbles flexibles et les connecteurs sont correctement fixés est crucial pour maintenir une connexion électrique fiable. Le routage précis des câbles aide à prévenir les contraintes et les dommages potentiels, qui pourraient affecter négativement le fonctionnement de l'interrupteur. Il est important de rester vigilant lors de l'attachement des connecteurs, en évitant les erreurs courantes comme un serrage excessif ou un mauvais alignement. Installer correctement ces composants garantit à la fois l'intégrité opérationnelle de l'interrupteur et sa durée de vie, ce qui améliore ainsi la solidité de votre équipement.

Éviter les erreurs courantes d'installation

Application incorrecte de l'adhésif

Une application incorrecte de l'adhésif est un piège fréquent qui peut considérablement compromettre la fonctionnalité et la durabilité des interrupteurs à membrane. Les erreurs courantes incluent une couverture insuffisante, ce qui peut entraîner des zones de l'interrupteur qui n'adhèrent pas correctement, et une application excessive, qui peut provoquer des fuites et des installations sales. Ces erreurs réduisent la durée de vie de l'interrupteur et son efficacité, pouvant entraîner des défaillances opérationnelles. Pour garantir une utilisation correcte de l'adhésif, suivez toujours ces conseils :

- Assurez une couverture complète : Appliquez soigneusement l'adhésif pour couvrir toute la surface sans laisser de vides afin d'éviter toute section desserrée.

- Évitez l'application excessive : Utilisez la quantité recommandée d'adhésif pour éviter les débordements ou les fuites sur les composants.

- Appliquer une pression uniforme : Pendant l'installation, appliquez une pression uniforme pour éviter les bulles d'air et garantir une fixation solide.

Ces lignes directrices visent à aider à éviter les erreurs courantes lors de l'application d'adhésifs et à garantir un processus d'installation réussi, améliorant ainsi à la fois les performances et la durée de vie.

Mauvaise manipulation du câble flexible

Une mauvaise manipulation des câbles flexibles peut entraîner des dommages importants ou un dysfonctionnement du commutateur membrane. Ces câbles sont essentiels pour établir des connexions électriques fiables, donc une manipulation soigneuse est cruciale pendant l'installation. Les erreurs telles que des pliures excessives ou un routage incorrect peuvent affaiblir ou casser les câbles, compromettant le fonctionnement du commutateur. Pour protéger les câbles flexibles, tenez compte des lignes directrices suivantes :

- Manutention Douce évitez de tordre ou de plier les câbles excessivement pour maintenir leur intégrité.

- Routage et positionnement corrects orientez les câbles le long de trajets lisses sans angles aigus pour réduire la contrainte et prévenir l'usure avec le temps.

- Connexions Sécurisées assurez-vous que tous les connecteurs sont fermement attachés pour éviter les déconnexions pendant l'utilisation.

Suivre ces pratiques aidera à maintenir la fonctionnalité du câble et contribuera à une opération stable et efficace du commutateur membrane.

Prévention de l'inversion de la coupole

L'inversion de la coupole est un problème sérieux qui peut affecter négativement la performance des commutateurs membrane, souvent causé par une application incorrecte de pression lors de l'installation. Ce phénomène entraîne l'effondrement de la coupole du commutateur, compromettant le retour tactile et la fonctionnalité. Pour éviter l'inversion de la coupole, utilisez des stratégies telles que :

- Application correcte de la pression : Lors de l'installation, appliquez une pression uniforme sur toute la surface du commutateur pour maintenir la structure de la coupole.

- Utilisation d'outils d'installation appropriés : Utilisez des outils conçus pour répartir uniformément la pression et éliminer le risque d'inversion de la coupole.

- Effectuer des vérifications après installation : Une fois installés, testez les commutateurs pour vous assurer qu'ils répondent correctement et vérifiez qu'il n'y a pas d'inversions de coupole.

Ces mesures préventives sont essentielles pour préserver l'intégrité des interrupteurs et leur fonctionnement après leur installation. En corrigeant ces erreurs courantes, on peut améliorer considérablement le processus d'installation des interrupteurs à membrane, garantissant un fonctionnement fiable et une durée de vie prolongée.

Options de commutateur de membrane supérieure pour différentes applications

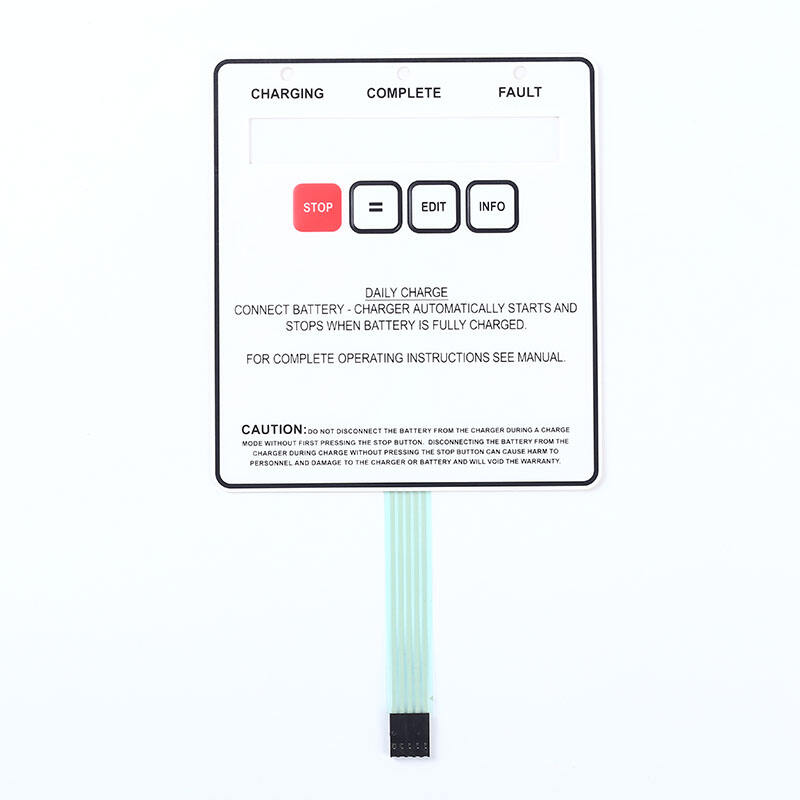

Caractéristiques du panneau de commutation à membrane

Les panneaux à interrupteurs membrane sont loués pour leurs fonctionnalités polyvalentes, qui répondent aux besoins variés de diverses applications, allant de l'industrie aux dispositifs médicaux. Les caractéristiques clés incluent le retour tactile, qui garantit que les utilisateurs ressentent une réponse physique lorsqu'ils appuient sur un bouton, améliorant ainsi l'ergonomie. La durabilité est un autre trait essentiel, permettant à ces interrupteurs de résister à des environnements sévères et à une utilisation intensive sans compromettre les performances. Les options de personnalisation sont nombreuses, permettant des conceptions spécifiques qui répondent aux exigences uniques de chaque application. Des technologies comme l'éclairage rétro-éclairé LED renforcent encore ces panneaux en améliorant la visibilité et en offrant un attrait esthétique. Ces attributs rendent les interrupteurs membrane hautement adaptables dans de nombreux secteurs, en améliorant l'efficacité opérationnelle et l'expérience utilisateur.

Fonctionnement des interrupteurs à membrane étanches

Les interrupteurs à membrane étanches jouent un rôle crucial dans les environnements où l'exposition à l'humidité ou aux liquides est prédominante, comme dans les espaces extérieurs ou les installations industrielles. Ils sont conçus avec des matériaux et des designs qui offrent une imperméabilité à l'eau, garantissant un fonctionnement fiable même dans des conditions difficiles. Des matériaux de haute qualité tels que le silicone et le polyester sont souvent utilisés, et des conceptions scellées aux coutures aident à obtenir l'étanchéité nécessaire. Plusieurs industries, y compris l'automobile, la marine et les fabricants d'équipements extérieurs, comptent sur ces interrupteurs pour maintenir la fonctionnalité et la sécurité, quelles que soient les conditions environnementales.

Avantages des interrupteurs à membrane en PET

Les commutateurs à membrane en polyéthylène téréphtalate (PET) se distinguent par leur flexibilité et leur durabilité, ce qui en fait un choix privilégié dans la conception d'interfaces modernes. Non seulement leur construction permet de les plier et de les manipuler de manière intensive, mais elle offre également une résistance exceptionnelle à l'usure et aux contraintes environnementales. En outre, le PET est un matériau respectueux de l'environnement et recyclable, conforme aux pratiques durables. La clarté et la sensibilité au toucher fournies par le PET améliorent les conceptions d'interfaces utilisateur, offrant des interactions transparentes et intuitives entre les applications.

Commutateurs FPC de qualité médicale

Dans les applications médicales, les interrupteurs à Circuit Imprimé Flexible (FPC) sont indispensables en raison de leur capacité à répondre aux exigences strictes de biocompatibilité et de stérilité. Ces interrupteurs sont conçus pour fonctionner sans défaut dans des environnements de soins où l'hygiène et la fiabilité sont primordiales. Le respect des réglementations et certifications médicales garantit leur adéquation dans des environnements critiques, où ils sont utilisés dans des appareils de diagnostic, des systèmes de surveillance des patients et d'autres équipements médicaux. Leur précision et leurs capacités de contrôle réactif sont essentielles à la sécurité des patients et à l'efficacité opérationnelle des établissements médicaux.

Applications des Membranes à Interrupteurs PCB

Les interrupteurs à membrane sur plaquette de circuit imprimé (PCB) sont connus pour leur polyvalence dans un large éventail d'industries, offrant une fiabilité accrue et des conceptions compactes. Ces interrupteurs sont habiles à gérer des configurations de circuits à haute densité tout en maintenant des capacités opérationnelles précises, les rendant idéaux pour les appareils électroniques grand public, les applications automobiles et les télécommunications. La nature robuste et l'utilisation efficace de l'espace des interrupteurs à membrane PCB permettent leur intégration dans des appareils complexes et compacts, mettant en avant leur applicabilité généralisée.

Actualités à la Une

-

Instructions pour l'échantillon de panneau à interrupteur membrane

2023-12-14

-

Connaissez-vous les raisons pour lesquelles les tranches de fondue ne remontent pas lorsque vous appuyez dessus ?

2023-12-14

-

Qu'est-ce qu'un guide de lumière ? Hongmao se spécialise dans la production de feuilles de guides de lumière, le saviez-vous ?

2023-12-14

-

Combien de règles sont nécessaires pour fabriquer un interrupteur membrane ?

2023-12-14

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI