Pay attention to the circuit layer material when buying a membrane switch!

Essential Membrane Switch Materials for Durability

Polyester vs. Polycarbonate Performance Comparison

When it comes to membrane switch materials, both polyester and polycarbonate offer unique benefits that contribute to their durability. Polyester is renowned for its flexibility and chemical resistance, which makes it an ideal choice for environments where the switch may be exposed to harsh substances. Its pliability allows it to withstand repeated use without cracking or degrading, making it a popular choice in industrial and automotive applications.

In contrast, polycarbonate is known for its impact resistance and strength, making it highly resilient in high-stress environments. This material can endure significant physical stresses without sustaining damage, which makes it suitable for applications in sectors like medical devices and control panels where visual feedback is crucial. A study in the electronics industry showed that polycarbonate overlays can withstand 200% more impact compared to polyester.

A comparative analysis across industries reveals that while polyester is favored in applications requiring repeated flexing and chemical exposure, polycarbonate's durability against physical stress makes it indispensable in areas demanding optical clarity and robustness. For instance, many medical and consumer electronics prefer polycarbonate overlays for their blend of strength and transparency, while industries dealing with chemicals lean towards polyester for its resistance.

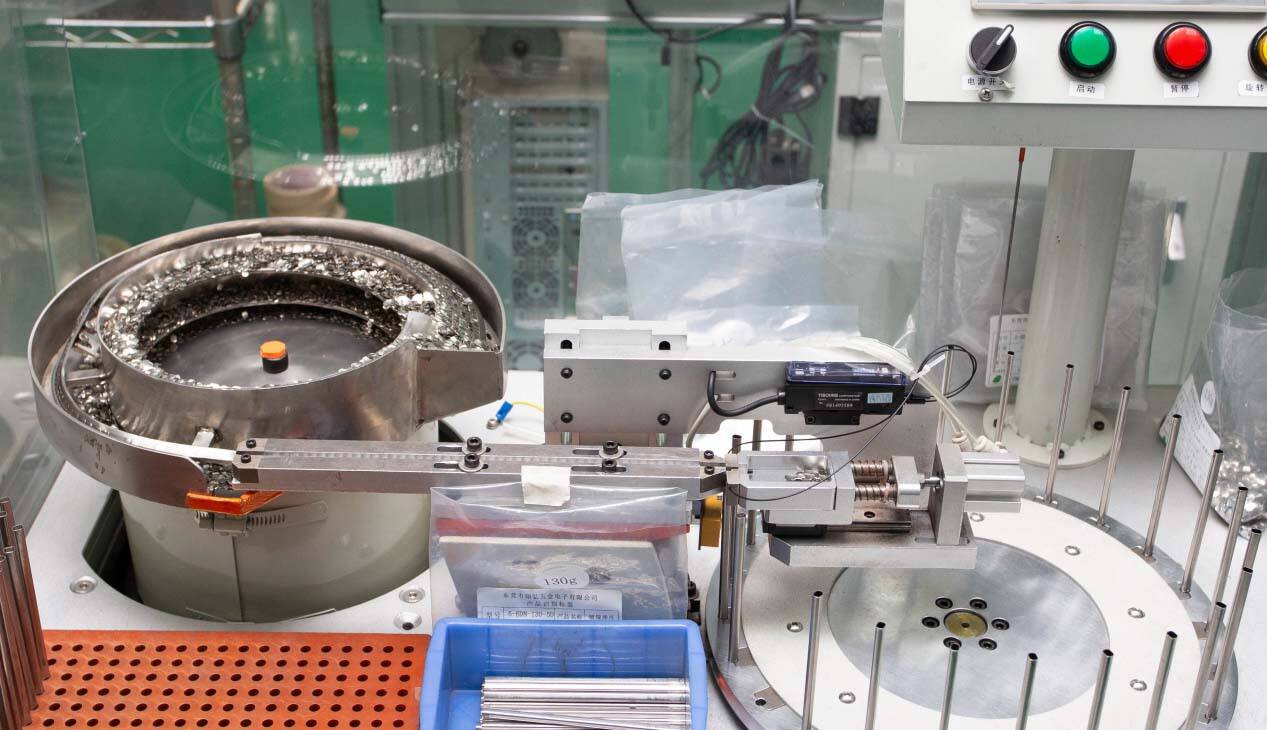

Metal Dome Selection for Reliable Actuation

Metal domes are essential components in membrane switches as they provide tactile feedback and reliable actuation. They ensure that each press is met with a satisfying click and consistent performance. When selecting metal dome materials, it's vital to consider factors such as fatigue resistance, conductivity, and durability. These ensure that the switch performs optimally over its lifespan.

The criteria for metal dome selection significantly impact the switch's lifecycle. Metal domes with higher fatigue resistance can withstand millions of actuations without failure, lowering replacement costs and downtime. Statistics suggest that switches with well-selected metal domes have an incidence of failure rate as low as 0.1% over millions of cycles. Proper selection not only enhances user experience with improved tactile feedback but also extends the device's functionality, making them a reliable choice for industries like consumer electronics and automotive controls.

To maximize the performance of membrane switches, choosing the right metal dome can make a substantial difference. This ensures that both durability and cost-effectiveness are achieved, as they reduce maintenance needs while providing the desired feedback and performance.

Adhesive Types for Secure Bonding

The adhesive in membrane switches is a crucial element that ensures secure bonding and contributes to the switch's overall durability. There are various adhesive types, including pressure-sensitive adhesives and epoxy adhesives, each offering different strengths in bonding and environmental resistance. Pressure-sensitive adhesives are often chosen for their ease of application and strong adherence, while epoxy adhesives are favored for their high environmental resistance and long-term stability.

Adhesives play a significant role in sustaining long-term functionality, particularly in environments exposed to varying temperature and humidity conditions. A reliable adhesive ensures the switch layers remain intact and fully operational, even under strenuous environmental conditions. According to market research, adhesives with high thermal and moisture resistance improve membrane switches' performance by up to 30% compared to standard adhesives.

By analyzing adhesive performance data and studying market comparisons across various bonding agents, it becomes clear that selecting the appropriate adhesive is not merely a matter of durability but a crucial factor in maintaining consistent switch performance throughout its lifecycle. Secure bonding paves the way for reliable operation in demanding applications and contributes to the overall success of a membrane switch's deployment.

Environmental Resistance in Membrane Switch Design

Waterproofing Techniques and Material Choices

Ensuring waterproof resilience in membrane switches is crucial to their performance in moisture-prone environments. Common techniques employed include encapsulation, which envelops switch components, protecting them from water ingress. Alternatively, gasket designs offer a physical barrier between switch layers to repel moisture effectively. Material selection significantly contributes to waterproof capabilities, with some switches opting for IP-rated alternatives that offer a standardized resistance level. This strategic approach is validated by statistics indicating a reduction in failure rates associated with moisture ingress when proper waterproofing solutions are implemented. Inadequate waterproofing can lead to costly damages and replacements, making these techniques and materials vital.

UV-Stabilized Materials for Outdoor Applications

Outdoor applications require robust materials that can withstand continuous exposure to UV radiation, which can deteriorate membrane switch integrity over time. UV-stabilized materials, such as UV-resistant polyester, effectively mitigate such risks by preventing color fade and maintaining structural integrity. The financial impact of UV damage is significant; therefore, investing in UV-stabilized solutions is both a preventive measure and a cost-effective strategy. Various studies demonstrate the superior performance of UV-stabilized membrane switches, highlighting their longevity in demanding outdoor conditions. Utilizing case studies provides quantitative evidence of the effectiveness of these materials in real-world scenarios, reassuring their capability in preserving functionality and appearance under harsh sunlight conditions.

Engineering Considerations for Material Optimization

Flexible Circuit Materials vs. Rigid Substrates

Flexible circuit materials offer distinct advantages over traditional rigid substrates, particularly in membrane switch applications. Due to their pliability, flexible circuits can be integrated into compact designs and curved surfaces, enhancing ergonomic features and saving space—a critical consideration for consumer electronics like smartphones and medical devices. However, they can be more susceptible to damage if bent excessively and may require careful handling. On the other hand, rigid substrates provide greater structural stability, which is beneficial for devices exposed to physical wear and tear. As product designs evolve, industry experts are increasingly prioritizing flexible circuit materials for their versatility and ability to meet varied application needs.

Layer Thickness Impact on Switch Performance

The thickness of each layer in a membrane switch assembly significantly influences its performance and user experience. While thicker layers can enhance durability and provide a firmer tactile response, they may compromise the switch's flexibility and add to the overall bulkiness. In contrast, thinner layers can improve sensitivity and responsiveness but might reduce durability. Optimizing layer thickness requires balancing application specifics and user requirements, often involving advanced materials engineering. Industry research suggests that membranes typically achieve optimal performance with layer thicknesses ranging from 0.3mm to 1.5mm, varying according to the switch type and intended use. This nuanced approach allows for precise customization that meets specific user needs while ensuring longevity and reliability.

High-Performance Membrane Switch Solutions

Waterproof Membrane Switches

Waterproof membrane switches are essential for environments where exposure to moisture is a concern. The design elements that make these switches waterproof primarily include material selection and construction techniques. Manufacturers often use specialized waterproof materials and sealing methods to ensure reliability. For instance, rubber or silicone seals are commonly employed to prevent water ingress, and specific adhesives add an extra layer of protection. Industries like marine and medical benefit greatly from these switches due to their durability.

Certification standards like Ingress Protection (IP) ratings are vital for these switches, indicating their water resistance level. For instance, an IP68 rating denotes that the device is dust-tight and can withstand continuous immersion in water, making it suitable for demanding environments. Case studies in sectors like agriculture and outdoor equipment demonstrate the successful application of these high-performance waterproof switches.

PET Membrane Switches

PET, or Polyethylene Terephthalate, offers unique properties that make it highly effective for membrane switches. Its popularity stems from its excellent resistance to wear and environmental factors, making it ideal for high-use applications. PET is favored in industries where durability and resistance to harsh chemicals or weather are crucial, such as automotive and industrial control panels. These qualities ensure the switches maintain functionality and appearance over extended periods.

However, PET switches have limitations compared to other materials, especially in applications requiring extreme flexibility or where aesthetic customization is a priority. While PET excels in durability, designers may opt for more versatile materials when these factors are critical, ensuring the switch meets all user and design requirements.

Hot News

-

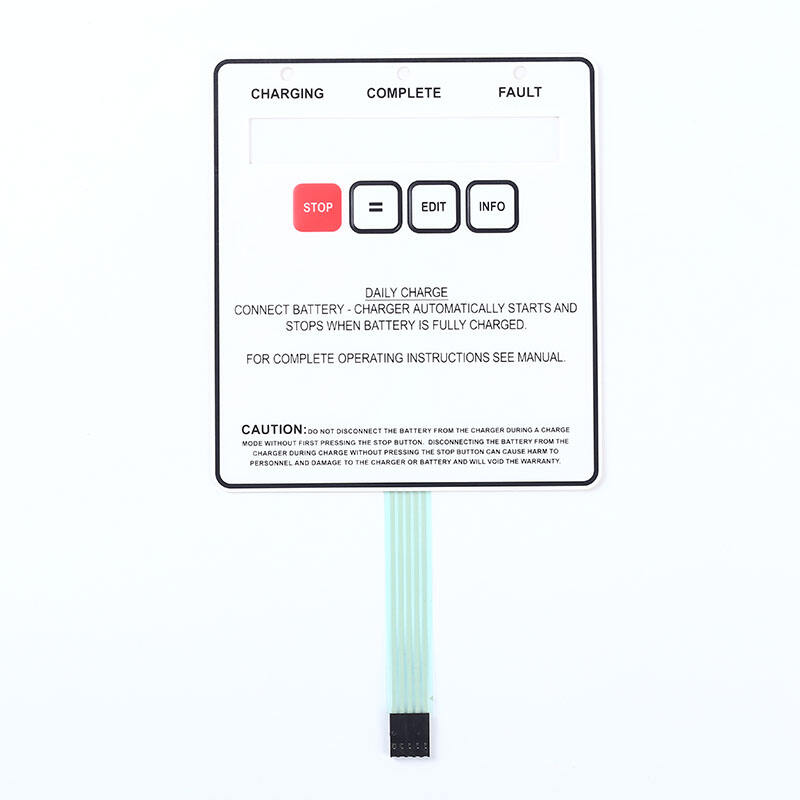

Membrane Switch Panel Sample Instructions

2023-12-14

-

Do You Know the Reasons Why Hot Pot Slices Cannot Pop Up When Pressed?

2023-12-14

-

What is a Light Guide? Hongmao Specializes in the Production of Light Guide Sheets, Did You Know?

2023-12-14

-

How Many Rulers Are Needed To Make A Membrane Switch?

2023-12-14

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI