Is it better to choose a membrane switch with a simple or complex design? Let's debate!

Key Design Considerations for Membrane Switch Panels

Balancing Simplicity and Functionality in Membrane Keyboard Layouts

Creating a user-friendly interface is essential for membrane keyboards, where intuitive design can significantly impact usability. Membrane keyboards benefit from well-thought-out layouts that make navigation easy and efficient, enhancing both user experience and aesthetic appeal. Successful examples, such as minimalist designs that reduce clutter and emphasize key functions, demonstrate improved usability without sacrificing the visually appealing aspects that are crucial for consumer electronics. User experience studies reveal that simplicity in keyboard layouts correlates with higher performance; for instance, a streamlined membrane keyboard design can boost typing speed and reduce errors, which is vital for productivity-focused applications.

Material Selection for Durable Membrane Switch Performance

Material choice plays a crucial role in the performance of membrane switches, affecting their durability and adaptability. Common materials like polyester and polycarbonate are frequently used due to their desirable characteristics such as resistance to wear and flexibility. For instance, polyester offers excellent chemical resistance, while polycarbonate provides robust flexibility. These properties ensure that membrane switches endure harsh conditions while maintaining functionality. Case studies, notably in industrial applications, have highlighted the long-lasting nature of switches crafted from these durable materials, showcasing their viability in environments demanding high performance and resilience. Exploring various materials helps tailor a membrane switch to specific needs, optimizing its longevity and utility.

Application-Specific Membrane Switch Design Requirements

Industrial vs Medical-Grade Membrane Switches Comparison

When designing membrane switches, it's crucial to meet specific application needs, particularly in medical-grade and industrial settings. Medical-grade switches must adhere to rigorous design standards due to higher safety and reliability requirements. This often involves strict compliance with regulatory bodies like the FDA, ensuring switches meet health and safety guidelines. In contrast, industrial switches might not require such stringent approvals but must still perform reliably under harsh conditions. A comparison of failure rates reveals that medical-grade switches often have lower failure rates due to these stringent standards, exemplifying their reliability over industrial applications.

Customization Options for Complex Membrane Circuit Patterns

Customization of membrane circuit patterns plays a pivotal role in catering to specific application needs. From color and graphics to specialized functionalities, there are numerous customization options available. These enhancements not only improve the aesthetics but also enhance usability and brand visibility. Custom designs can transform a standard membrane switch into one that can offer specialized inputs and controls tailored to unique system requirements. For instance, in automotive applications, complex circuit designs integrated into dashboards have successfully increased operational efficiency and brand distinction. The ability to tailor circuit patterns allows businesses to create interfaces that not only perform well but also promote their brand identity effectively.

Featured Membrane Switch Products for Different Use Cases

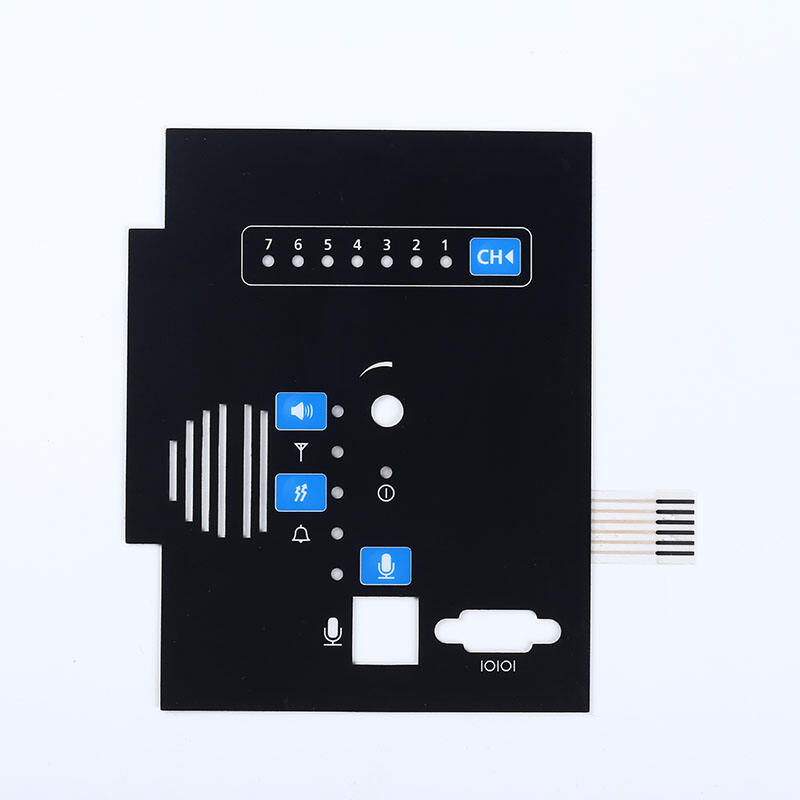

Membrane Keypad - Standard Interface Solution

The membrane keypad is a cost-effective and versatile interface solution widely adopted across various applications, particularly in consumer electronics. These keypads are favored for their sleek, low-profile design, which integrates seamlessly with modern devices, offering a tactile user experience. In consumer electronics, membrane keypads are commonly used in remote controls, microwaves, and security systems. Customers appreciate their durability and ease of use, often highlighting these aspects in user feedback. According to market trends, there is an increasing demand for membrane keypads, driven by the continuous growth of consumer electronics. This trend suggests that membrane keypads will remain a popular choice due to their affordability and practicality.

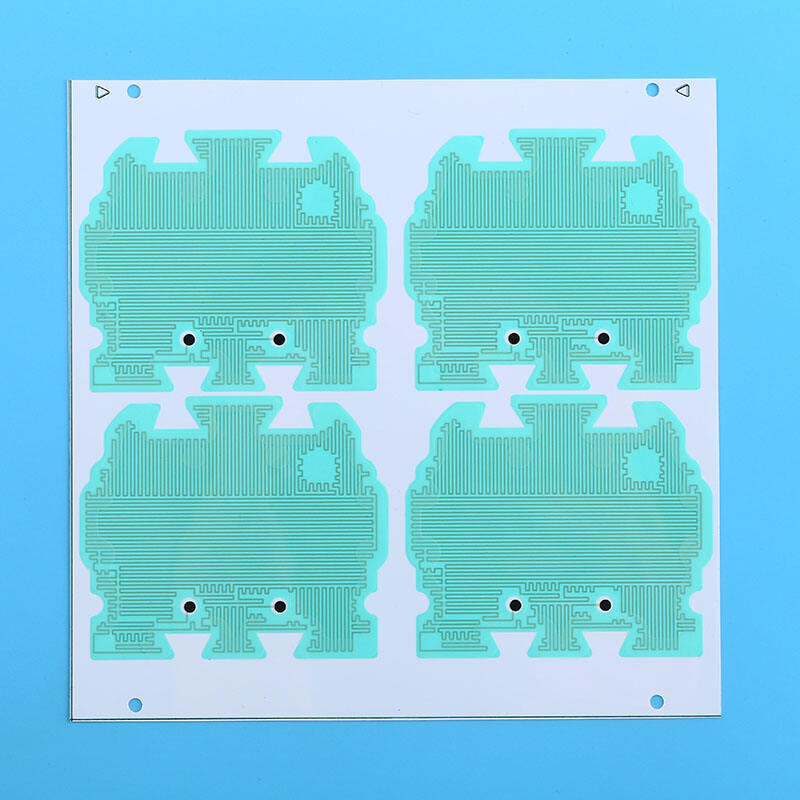

Medical Treatment FPC Membrane Switch - Flexible Circuit Design

Flexible Printed Circuits (FPC) play a crucial role in medical membrane switches by offering lightweight, space-efficient, and highly adaptable design solutions for medical devices. An FPC's flexibility allows it to fit into compact spaces, making it ideal for devices like portable heart rate monitors and handheld diagnostic tools. Moreover, FPC designs provide exceptional reliability, a necessity in the sensitive medical field where device failure is not an option. Several medical device manufacturers have lauded the efficacy of FPC designs, emphasizing their contribution to product innovation and patient safety. The versatility and efficacy of FPC technology continue to make it a preferred choice in the medical industry.

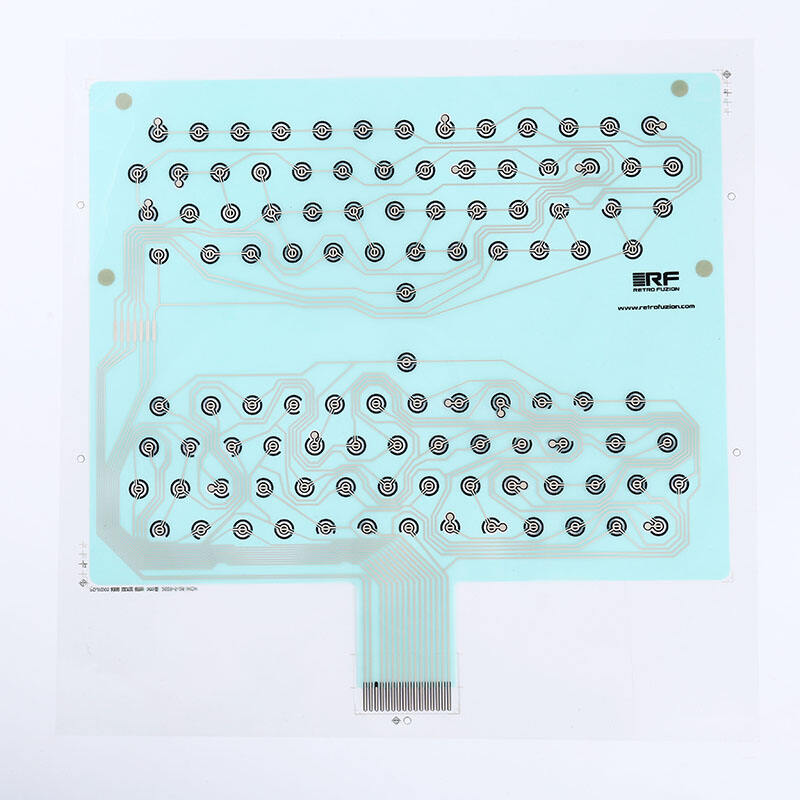

Tamper-Proof Circuit Security Features

The need for enhanced security features in membrane switches is increasingly crucial, especially in environments where data integrity and user privacy are paramount. Tamper-proof circuits offer robust protection mechanisms designed to detect and prevent unauthorized access or alterations to the switch's functionality. These circuits are particularly effective in sensitive environments such as financial institutions and secure access points. Recent studies indicate a significant reduction in security breaches and data tampering incidents when employing tamper-proof designs. This technology continues to evolve, offering ever-more advanced levels of security for a range of applications demanding stringent protection measures.

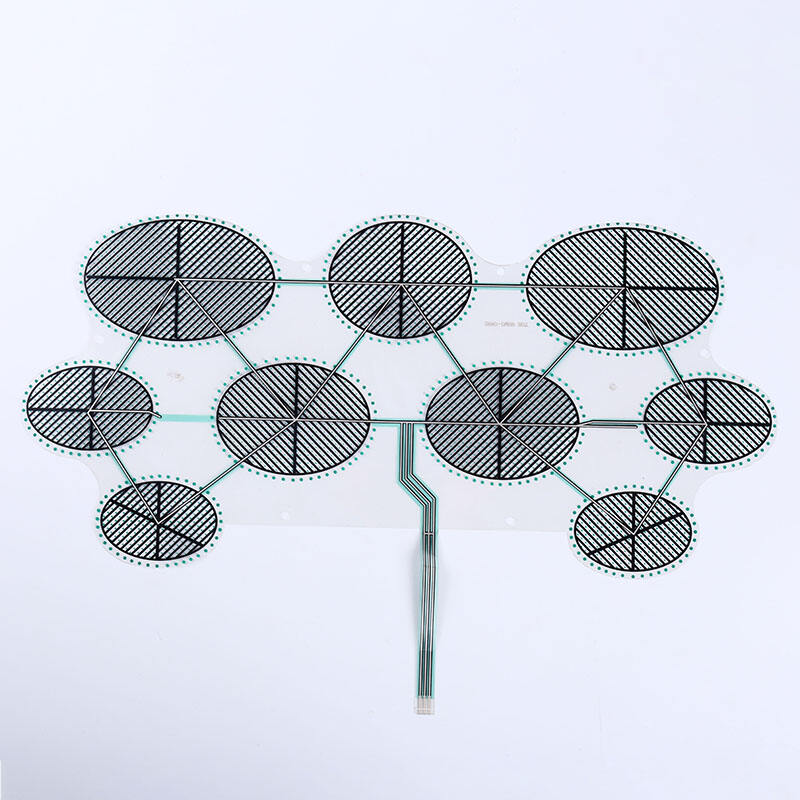

High-Durability Membrane Circuit Switch Configurations

In industrial applications where wear and tear are significant, high-durability membrane circuit switch configurations are indispensable. These switches are engineered with design techniques that enhance longevity, such as thicker overlays or reinforced materials, ensuring they withstand harsh environments. For instance, switches with thicker overlays are less prone to deterioration under intense use, making them ideal for machinery control panels in manufacturing plants. Reinforced materials protect against abrasions and chemical damage, further extending the life span of these switches. Industry ratings highlight the superior durability of such configurations, which consistently outperform standard designs in demanding applications.

Specialized Membrane Switch Panel Customizations

In the landscape of niche markets, there's a growing trend towards the specialization of membrane switch panels tailored to specific industry needs. For instance, aerospace applications require panels with specific environmental resistance capabilities, while the automotive industry demands high durability under variable conditions. Custom designs affordously meet these unique industry requirements and enhance the final product's functionality. Successful implementations abound, such as the use of specialized panels in aircraft cockpits for improved tactile feedback and automotive dashboards for enhanced visual control. As industry needs evolve, customized panels increasingly serve as a key differentiator for companies seeking to optimize usability and performance.

Evaluating Reliability in Membrane Switch Designs

Testing Protocols for Membrane Keyboard Longevity

Testing protocols play a crucial role in evaluating the longevity and reliability of a membrane keyboard. Commonly, these protocols assess aspects like wear and tear endurance, key actuation force, and tactile feedback resilience over time. Metrics such as keypress lifespan, often measured in millions of actuations, serve as critical benchmarks for durability assessments, informing designers about potential product weaknesses. Findings from independent studies consistently highlight disparities in longevity across various manufacturers, emphasizing the need for thorough testing. For example, a study might reveal that while one brand's membrane switch can endure up to 5 million presses, another reaches 10 million, making it a more robust option in heavy-use scenarios.

Environmental Resistance in Complex Switch Layouts

Membrane switches, including membrane keyboards, must withstand a range of environmental challenges, such as humidity, pressure, and temperature variances. Such factors can reduce reliability, especially in complex switch layouts. To combat these challenges, designers often employ strategies such as the use of moisture-resistant materials, sealing techniques to prevent dust ingress, and temperature-tolerant components. Research supports these methods, showing a significant reduction in failure rates when such precautions are implemented. For example, switches exposed to extreme conditions demonstrated up to a 30% lower failure rate when fortified with advanced environmental resistance measures compared to those without such enhancements. These strategies ensure that membrane switches function consistently, even in demanding settings.

Cost Analysis of Simple vs Complex Membrane Switch Patterns

Prototyping Considerations for Membrane Circuit Development

Prototyping membrane circuits involves weighing cost implications and design considerations. Simple designs often take less time and materials to develop, leading to lower initial costs. However, complex systems provide enhanced functionalities, albeit at a higher cost. The trade-offs between simplicity and complexity during prototyping are crucial. Simple designs might offer ease of production and reduced expenses, while complex designs can deliver superior performance and versatility. Industry insights reveal that the average prototyping costs can vary significantly based on the design's complexity. Generally, simpler designs can cost significantly less than intricate ones when factoring in material choice and iterative testing.

ROI Calculation for Advanced Membrane Switch Features

Accurately calculating ROI for advanced features in membrane switches involves assessing several factors. Increased efficiency, reduced maintenance costs, and enhanced durability can significantly boost the ROI. To begin, evaluate the cost of integrating advanced features against potential savings in operational costs and enhanced performance. ROI is influenced by factors such as improved user experience, decreased downtime, and lower repair frequencies. Demonstrating successful ROI calculations requires analyzing scenarios where advanced features lead to tangible benefits, justifying their upfront costs. For example, a complex membrane switch panel might require a higher initial investment but could save costs over time through reduced maintenance and increased product lifespan.

Hot News

-

Membrane Switch Panel Sample Instructions

2023-12-14

-

Do You Know the Reasons Why Hot Pot Slices Cannot Pop Up When Pressed?

2023-12-14

-

What is a Light Guide? Hongmao Specializes in the Production of Light Guide Sheets, Did You Know?

2023-12-14

-

How Many Rulers Are Needed To Make A Membrane Switch?

2023-12-14

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI