The strict quality inspection system guarantees the outstanding quality of membrane switches.

Key Inspection Practices for Membrane Switches

Material Quality Verification for Membrane Keypads

Selecting high-quality materials is fundamental to enhancing the durability and functionality of membrane keypads. The durability of a membrane switch largely depends on the materials used, affecting everything from tactile feedback to lifespan. To ensure quality, manufacturers often rely on supplier certifications and adhere to stringent in-house testing protocols. These protocols are designed to verify material strength, flexibility, and resistance to environmental factors. A robust verification process can prevent the issues caused by inferior materials, such as premature wear and high failure rates. For example, low-quality materials in a membrane keyboard may lead to increased malfunctions over time, spiking warranty claims and customer dissatisfaction.

Contact Resistance Testing Protocols

Measuring contact resistance is crucial for the dependable performance of membrane switches throughout their operational life. In this testing protocol, standardized equipment, such as digital multi-meters, are used to measure the resistance levels at specific points in the switch, ensuring they remain within set parameters. Typically, lower resistance levels correlate with prolonged product lifespan and better user experience. Statistical insights reveal that maintaining optimal resistance levels can drastically extend the functionality and service life of the switch components. For industrial applications, it’s recommended to perform these resistance tests regularly to maintain consistent performance standards and prevent unexpected failures.

Tactile Response Consistency Checks

Ensuring tactile response consistency is key to providing satisfactory user experiences with membrane switches. User satisfaction hinges on the uniformity of tactile feedback, evaluated by measuring actuation force and assessing the response during prolonged use. Different methodologies, including using specialized machines to simulate repeated usage, offer insights into the long-term reliability of the product. Experts often emphasize that consistent tactile response is particularly important in fields like healthcare and retail, where precise user feedback is essential. Implementing iterative testing practices, informed by user feedback, can significantly enhance the product design, tailoring it to specific consumer needs.

Environmental Stress Testing Procedures

Membrane switches can be subjected to a variety of environmental conditions, including fluctuations in humidity, temperature extremes, and chemical exposures. The purpose of environmental stress testing is to simulate these real-world challenges to ensure switches maintain functionality. Such testing involves theories based on stress endurance and failure analysis, aiming to predict product performance under specified conditions. Data supports the necessity of rigorous environmental testing, highlighting potential failure rates when exposed to harsh environments. Tailoring protocols to suit different industries enhances the reliability of switches, ensuring they meet specific application demands, thereby reinforcing durability and customer trust.

Advanced Testing Methodologies

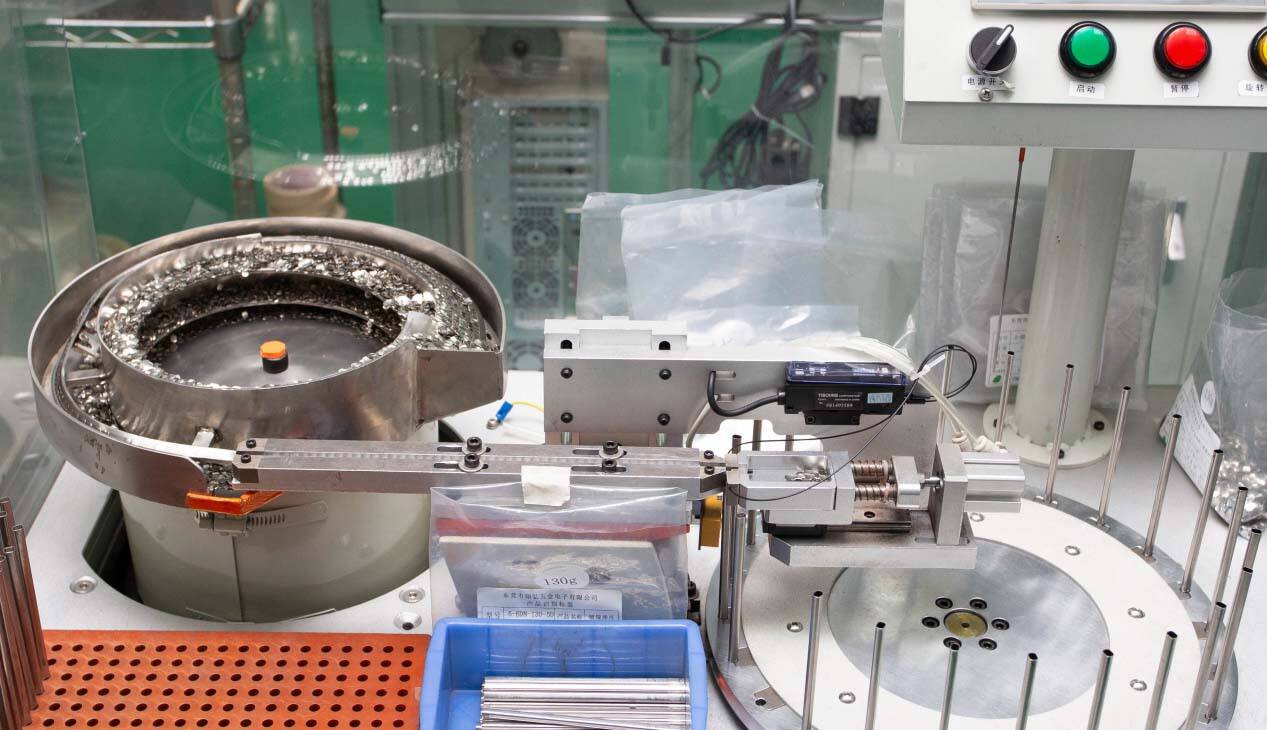

Lifecycle Testing for Membrane Keyboard Durability

Lifecycle testing is essential for predicting the longevity of membrane keyboards and their components. During this process, repetitive motion simulations and fatigue testing are meticulously conducted to assess durability. These methodologies reveal crucial data, such as the average lifespan of a membrane keyboard, with standardized tests showing a typical durability range that informs both product development and consumer warranties. By ensuring the accuracy and reliability of lifecycle testing data, manufacturers can offer warranties that boost customer confidence, knowing that their product can withstand the demands of frequent usage.

ESD and EMI Shielding Validation

Understanding Electrostatic Discharge (ESD) and Electromagnetic Interference (EMI) is key when ensuring the seamless functioning of membrane switches. Both factors can significantly affect a device's performance, requiring rigorous validation of ESD and EMI shielding. Testing protocols include simulating conditions under which ESD and EMI might occur, with benchmarks set to verify the effectiveness of the shielding. Studies have shown that products lacking adequate shielding are prone to higher failure rates, leading to compromised performance. As industry standards evolve, keeping up with advancements and aligning with compliance requirements is essential to maintaining membrane switch functionality and ensuring market competitiveness.

Premium Membrane Switch Solutions

Membrane Switch Panel: Industrial-Grade Reliability

Industrial-grade membrane switch panels are designed to offer unmatched durability and operational reliability, making them integral components in various industries. These panels are certified to meet stringent operational standards, ensuring compliance with industry-specific certifications such as UL and CE. For instance, numerous testimonials from manufacturers highlight the consistent performance and reliability of these panels in harsh environments, like automotive and industrial machinery sectors. The market demand for such robust solutions is ever-growing, as industries increasingly seek systems that can withstand rigorous conditions, addressing the need for both durability and efficiency in operations.

Medical Treatment FPC Membrane Switch: Sterile Compliance

Medical-grade membrane switches, particularly the FPC membrane switch, are developed with impeccable sterile compliance to ensure patient safety. These switches undergo stringent production and testing processes to guarantee cleanliness, minimizing infection risk in medical environments. Regulations by health authorities like the FDA and ISO 13485 guide these processes, dictating the safe use of electronic components in medical devices. Innovations such as antimicrobial coatings further enhance the switches' performance, offering additional layers of protection and meeting the ever-evolving standards of patient care and device safety.

LED Membrane Switch: Integrated Illumination Features

The LED membrane switch stands out with its integrated illumination features, enhancing visibility and usability dramatically. These switches offer various design options and configurations to boost aesthetic value and functionality. Consumer preferences indicate a significant inclination towards illuminated switches, due to improved operational efficiency and enhanced user experience. Case studies reveal scenarios where LED features have facilitated better user interactions, demonstrating the substantial advantages of illumination in various applications, from consumer electronics to industrial equipment.

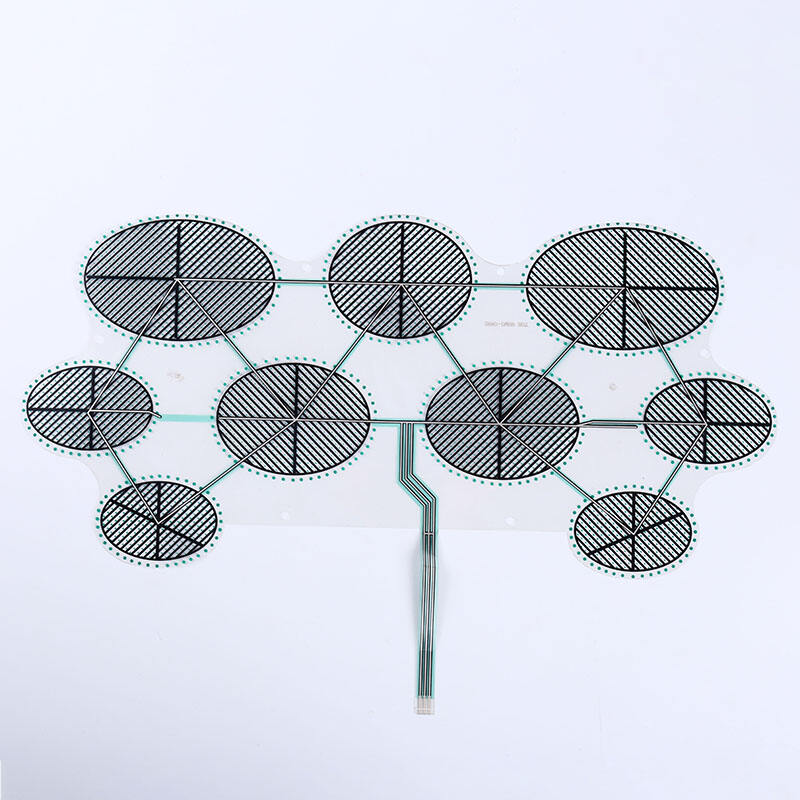

Membrane Circuit Switch: Precision Conductive Pathways

Conductive pathways are pivotal in determining the effective functionality of membrane circuit switches, playing a crucial role in guaranteeing optimal performance. Precision manufacturing techniques ensure these pathways are consistently reliable, meeting high industry standards for conductive materials. Real-world examples illustrate the consequences of faulty pathways leading to product failure, underscoring the necessity for meticulous quality control. This emphasis on precision ensures these switches meet operational needs, from consumer electronics to specialized industrial applications.

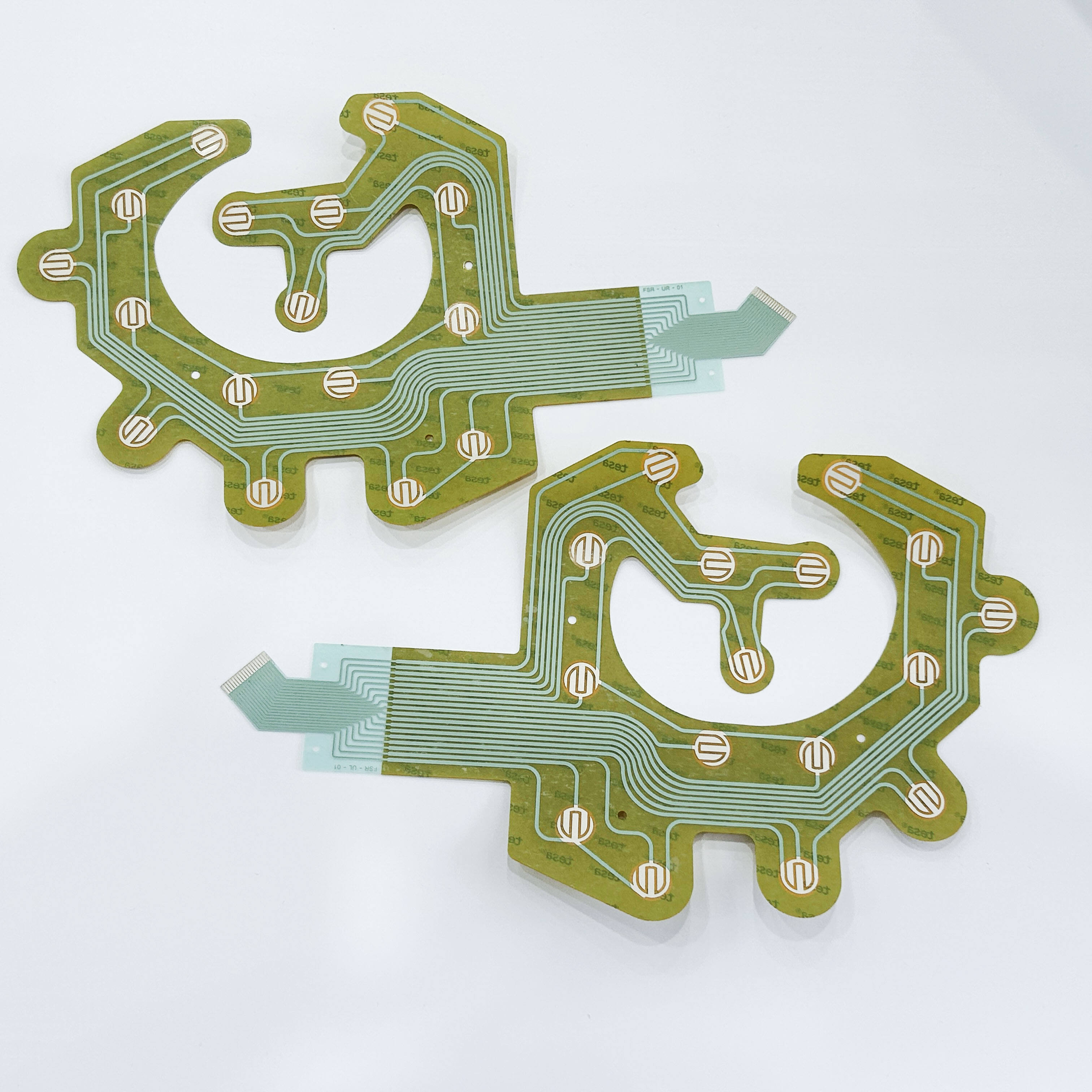

Soft Circuit Membrane Switch: Flexible Interface Design

Soft circuit membrane switches demonstrate exceptional adaptability and flexibility in interface design. Technological advancements in materials, such as bendable substrates, greatly enhance performance and user experience. These switches prove particularly beneficial in sectors like consumer electronics and automotive industries, where flexibility drives innovation. Insights from industry experts reveal that the future of soft circuit technology lies in expanding its applications, paving the way for more versatile and effective solutions.

Compliance & Industry Standards

ISO 9001 Certification Requirements

ISO 9001 certification plays a vital role in the membrane switch manufacturing industry, emphasizing a company’s commitment to quality management. Obtaining this certification requires adherence to stringent criteria, including customer focus, leadership engagement, process approach, and continual improvement. Companies that achieve ISO 9001 compliance often experience enhanced efficiency, reduced waste, and improved profitability; for instance, manufacturers like RSP have benefitted from these standards by optimizing production processes. Continuous audits and evaluations are integral to maintaining this certification, ensuring that organizations consistently meet quality benchmarks and adapt to any process changes, leading to sustained operational excellence.

ASTM Testing Guidelines for Membrane Switches

The ASTM guidelines provide a framework for conducting rigorous testing of membrane switches to verify safety and reliability across diverse application environments. These guidelines include specific tests such as resistance measurement, lifecycle durability, and environmental stress tests—critical for ensuring high-performing, reliable products. For example, statistics reveal that adherence to ASTM standards can significantly reduce failure rates in membrane switches, underscoring the importance of compliance. As testing methodologies evolve, manufacturers align with current ASTM standards to incorporate innovative techniques, guaranteeing products meet emerging industry needs and maintaining competitiveness in technology advancements.

Hot News

-

Membrane Switch Panel Sample Instructions

2023-12-14

-

Do You Know the Reasons Why Hot Pot Slices Cannot Pop Up When Pressed?

2023-12-14

-

What is a Light Guide? Hongmao Specializes in the Production of Light Guide Sheets, Did You Know?

2023-12-14

-

How Many Rulers Are Needed To Make A Membrane Switch?

2023-12-14

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI