Have you ever wondered about the different printing methods for membrane switches?

Essential Printing Methods for Membrane Switches

Screen Printing: The Industry Standard

Screen printing stands as the industry standard for producing membrane switches due to its reliability and cost-effectiveness. It provides high opacity and excellent adhesion, which are essential for the durability these switches require. Extensive industry reports highlight that up to 70% of membrane switches utilize screen printing, underscoring its widespread adoption and trustworthiness. This printing method ensures that the functionality of the switches is not compromised over time while maintaining the vividness of colors, which is crucial for clear visibility.

Digital Printing for Complex Designs

Digital printing has ushered in a new era for membrane switch production by enabling complex designs that are customizable. This method is particularly beneficial for short runs, reducing both waste and production time compared to traditional methods. Industry studies suggest that digital printing applications offer a 30% increase in design flexibility within the membrane switch sector. Such flexibility allows manufacturers to cater to specific design requirements, thus meeting diverse and sophisticated demands. Digital printing is transforming the way membrane keyboards are produced, making them more adaptable and visually compelling.

Flexographic Printing for High-Volume Production

Flexographic printing is recognized for its speed and efficiency in large-scale manufacturing, making it ideal for high-volume orders of membrane switches. Its capability to print on various substrates enhances production versatility, allowing for a broad range of application possibilities. According to an industry analysis, flexographic printing accounts for approximately 20% of all membrane switch productions, indicating its pivotal role in handling bulk orders efficiently. This method allows for consistent quality, which is crucial for maintaining standards in mass production, and it's particularly useful when dealing with keyboard membrane and similar products.

UV Inkjet Printing Advantages

UV inkjet printing brings to the table the unique advantage of immediate ink curing, resulting in quicker turnarounds for membrane switch production. This method facilitates the creation of vibrant colors and detailed images, lending itself well to high-quality applications. Expert insights indicate that UV inkjet printing has seen over a 15% increase in popularity within the membrane switch sector, highlighting its growing significance. It is particularly suitable for applications where aesthetic appeal is as important as functionality, thus broadening the scope of membrane switch utility in various industries. This technique is an excellent choice for producing membrane switches where quality and detail are paramount.

Material Considerations in Membrane Switch Manufacturing

Polycarbonate vs Polyester Substrates

When manufacturing membrane switches, the choice between polycarbonate and polyester as substrates is crucial due to their specific benefits. Polycarbonate is lauded for its impact resistance and optical clarity, making it suitable for high-performance environments where durability and visibility are paramount. This material is often selected for applications requiring fine detail, such as in display windows and intricate overlays. On the other hand, polyester is prized for its superior chemical resistance, which is ideal for environments where harsh substances are prevalent, such as in industrial and medical applications. Research highlights that approximately 60% of manufacturers opt for polyester due to its enhanced longevity in tough conditions, as it effectively withstands abrasive cleaning agents and physical stress.

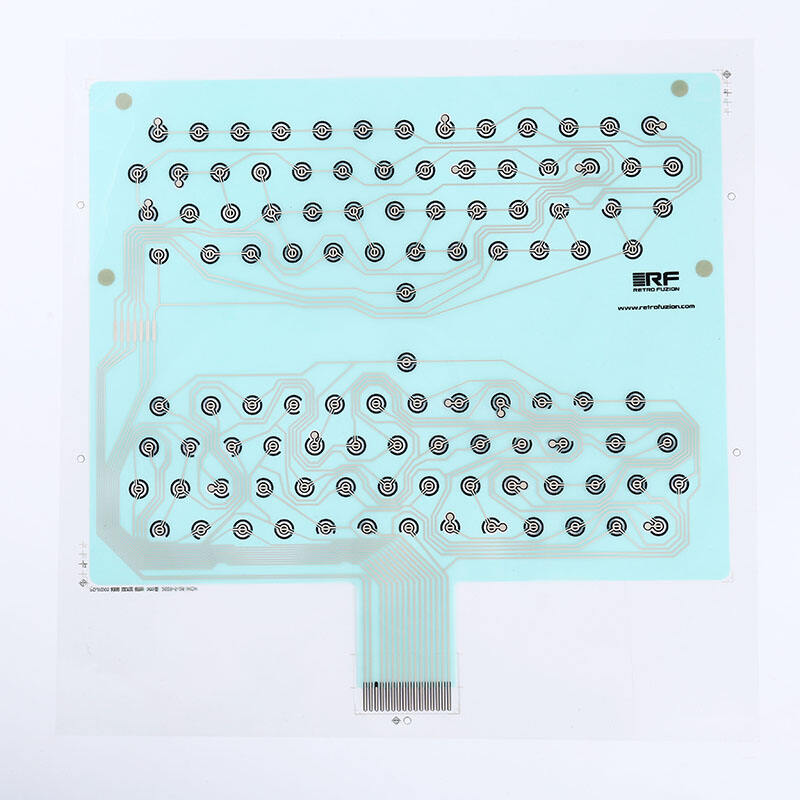

Conductive Ink Selection Criteria

Choosing the appropriate conductive ink is pivotal for ensuring the functionality and reliability of membrane switches. Key selection criteria include electrical conductivity, compatibility with substrates, and adherence to durability standards. Conductive inks must seamlessly integrate with the specific materials used in the layers of the membrane keyboard, ensuring consistent electrical performance. Industry experts strongly recommend testing these inks under varying conditions to ascertain their performance and reliability over time. This rigorous evaluation helps prevent failures and maintains the integrity of the electrical pathways within the membrane switch, ensuring a high-quality product.

Adhesive Layer Compatibility

The compatibility of the adhesive layer is vital to the structural integrity and operational performance of membrane switches. Different adhesives offer distinct advantages; for instance, some provide superior thermal resistance, crucial for high-temperature environments, while others enhance bonding strength, vital for durability under physical stress. It is imperative to conduct adhesion tests to determine which adhesive best fits the specific applications in membrane switch manufacturing. This ensures that the adhesive layer effectively maintains bond integrity under various environmental conditions and mechanical demands, thus prolonging the switch’s lifespan and reliability.

Key Membrane Switch Products and Their Applications

Membrane Switch Panel

Membrane switch panels are vital components serving as the user interface for various electronic devices, providing both enhanced usability and aesthetics. They are extensively used in consumer electronics, automotive controls, and medical devices, offering a seamless user experience that meets high expectations. Industry reports highlight a steady demand growth of 10% annually for these panels, emphasizing their integral role in maintaining streamlined operations. This increased demand underscores the necessity for manufacturers to continuously innovate, ensuring that these panels offer both attractive designs and functional benefits.

PCB Membrane Switch

PCB membrane switches integrate printed circuit boards, resulting in improved functionality and compact design, making them highly suited for mobile devices. These switches provide reliable tactile feedback and multifaceted controls, enhancing the user experience significantly. As devices become smaller and more capable, the demand for PCB membrane switches becomes more pronounced. Data suggests that these switches are expected to expand in demand by 12% over the next five years, making them a critical component in future electronic innovations.

Remote Control Membrane Switch Panel

Remote control panels frequently utilize membrane switches due to their lightweight and user-friendly interface, crucial for consumer electronics and home automation. This design aspect makes these panels prevalent in industrial equipment as well. Market trends indicate a significant growth opportunity, forecasting a 15% increase in sales for remote control panels using membrane switches. This growth mirrors a rising demand for more efficient and intuitive remote control solutions that ease the complexity of device management.

Membrane Circuit Switch

Membrane circuit switches effectively blend functionality with space-saving design, catering to the increasing need for compact applications. Their use spans various fields, from medical devices to control panels in aerospace technology, underscoring their versatility. An analysis suggests a consistent rise in demand, driven by the need for compact control solutions. This aligns with global trends toward miniaturization and increased device efficiency across several industries.

LED Membrane Switch

LED membrane switches incorporate lighting to enhance visibility in low-light conditions, greatly improving user interaction by combining style with functionality. Predominantly used in automotive interiors and appliances, these switches provide both aesthetic appeal and practical benefits. Reports indicate a growing market for LED-enhanced membrane switches, predicting a robust growth rate of 18%. This growth reflects an industry trend toward incorporating flexible lighting solutions into user interfaces for enhanced user experience and device appeal.

Durability Testing for Printed Membrane Keypads

Scuff Resistance Standards

Scuff resistance is a critical standard for assessing the durability of printed membrane keypads. This testing involves applying specific pressures to the keypad surface and observing any visible wear over time. To ensure that products meet high-quality standards, industry regulations set specific benchmarks that manufacturers must adhere to. By following these scuff resistance benchmarks, we can guarantee that our keypads maintain their integrity and function effectively even under frequent use. This process is vital for confirming the robustness and longevity of membrane switch products.

Chemical Exposure Testing

Chemical exposure testing is essential for evaluating the resilience of membrane keypads when exposed to various substances. This testing protocol involves subjecting the keypads to a range of chemicals to identify any degradation or failure points in the materials used. Understanding how these materials react under chemical exposure helps determine the lifecycle of membrane switches and their applicability across different industries. The results gained from chemical exposure testing are invaluable for predicting how membrane keypads will perform in real-world environments, ensuring that they meet the necessary durability requirements for their intended applications.

Temperature Tolerance Verification

Temperature tolerance verification involves rigorously assessing the performance of membrane keypads under extreme thermal conditions. We conduct these tests by exposing the keypads to a range of temperatures to simulate real-world applications and ensure their durability in various environments. Through analysis of the test results, we can identify any weaknesses and make necessary improvements in the design or material selection, resulting in higher-quality products. Ensuring that membrane keypads withstand extreme temperatures is crucial for their reliable performance in diverse operational settings.

Customization Options in Membrane Switch Printing

Tactile Response Engineering

Tactile response engineering is dedicated to crafting a feedback system within membrane switches that substantially enhances user experience. By selecting various materials and designs, manufacturers can significantly customize the interaction between the user and the device. Studies reveal that tactile responses that are effectively engineered can boost user satisfaction by as much as 40%, underscoring the importance of precise response mechanisms in increasing consumer engagement. This facet is crucial since it aligns product functionality with user expectations, leading to higher loyalty and adoption rates.

Backlighting Integration Techniques

Incorporating backlighting into membrane switches is a pivotal technique for improving visibility and usability in low-light conditions. Techniques vary widely, from strategic LED placement to advanced fiber optics systems, all aimed at creating an engaging and visually appealing interface. Recent consumer preference surveys indicate a 25% increase in demand for illuminated membrane switches, highlighting the growing importance of enhancing aesthetic quality and operational efficiency. These techniques not only boost user satisfaction but also expand the application possibilities across various environments, making the switches versatile and practical.

Branding and Graphic Design Considerations

Branding is essential in the design of membrane switches, as it significantly influences their identity and market appeal. Careful graphic design considerations, such as selecting appropriate color schemes, strategically placing logos, and providing interaction cues, play a crucial role in guiding users and reinforcing brand identity. Statistics show that a well-designed membrane switch can improve brand recognition by over 30%, emphasizing the strong connection between effective graphic design and product success in the marketplace. This enhances both visual appeal and operational functionality, contributing to a memorable user experience and solidifying brand loyalty.

Future Trends in Membrane Keyboard Technology

Smart Surface Integration

Smart surface integration is a cutting-edge trend in membrane keyboard technology, merging touch technologies with traditional membrane switches for enhanced interactivity. This convergence is evident in IoT devices, where intuitive interfaces significantly improve user engagement. By incorporating smart surfaces, manufacturers can create responsive designs that cater to the evolving needs of tech-savvy consumers. Market forecasts indicate a substantial surge in smart surface products, with anticipated growth rates reaching nearly 25%. As we move closer to a more interconnected world, the integration of smart surfaces in keyboards will become paramount.

Sustainable Printing Practices

The importance of sustainable printing practices is increasingly acknowledged in the membrane switch industry, driven by rising environmental concerns. These practices include the use of eco-friendly inks and materials, alongside optimization of waste management processes to minimize ecological footprints. Industry experts highlight a growing consumer demand for sustainable products, marking eco-friendly practices as a competitive advantage. As organizations strive to align with global sustainability goals, adopting environmentally conscious printing methods becomes crucial in establishing market leadership and fulfilling consumer expectations.

Nanotechnology in Conductive Inks

Nanotechnology is reshaping the landscape of conductive inks, offering superior conductivity properties that drive innovations in membrane switch designs. These advanced inks enable more compact and efficient designs, unlocking new possibilities in the creation of membrane switches. Due to its groundbreaking advantages, the adoption of nanotechnology in conductive inks is projected to witness significant growth, with market studies forecasting an expansion of up to 30%. This transformative technology not only enhances functionality but also supports miniaturization and robustness, paving the way for future technological advancements.

Hot News

-

Membrane Switch Panel Sample Instructions

2023-12-14

-

Do You Know the Reasons Why Hot Pot Slices Cannot Pop Up When Pressed?

2023-12-14

-

What is a Light Guide? Hongmao Specializes in the Production of Light Guide Sheets, Did You Know?

2023-12-14

-

How Many Rulers Are Needed To Make A Membrane Switch?

2023-12-14

EN

EN

AR

AR

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

VI

VI