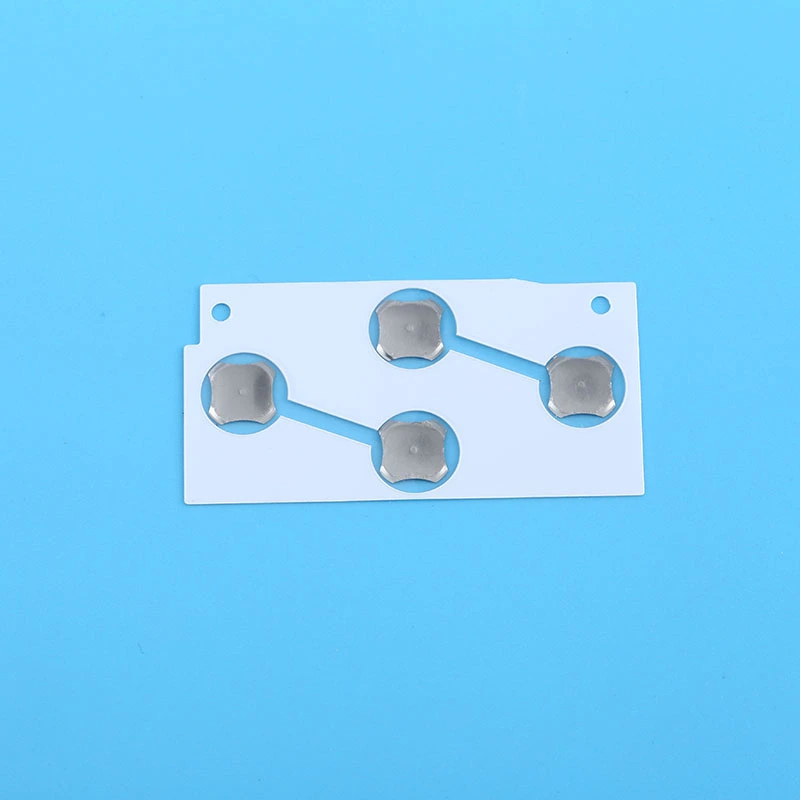

Metal Dome Arrays, also known as metal snap domes, are momentary switch contacts that become tactile switches when used with a printed circuit board, flex circuit, or membrane. Made of stainless steel, they come in various shapes like round, four-leg, triangle, oblong, and custom.

Essentially, a Metal Dome Array is a double-sided adhesive PET array carrying the metal dome as a contact switch. Placed on a PCB PAD or membrane switch, it enhances assembly speed and precision. The structure can be single layer, double layer, rubber glue, EMI printing, or Light Guide Film (LGF).

Choosing us is your biggest advantage. Our products are cheap and of high quality, allowing your products to have excellent performance. HONGMAO----Your unique choice

Metal dome arrays stand out for their precision in providing tactile feedback in electronic interfaces. These arrays, composed of small, dome-shaped metal elements on a circuit board, play a crucial role in ensuring accurate and reliable button presses.

The manufacturing process involves intricate shaping and plating of metal domes to achieve consistent actuation force and tactile response. This precision not only enhances the user experience by delivering a satisfying touch but also contributes to the overall durability and longevity of electronic devices.

In applications ranging from industrial control panels to medical equipment, the precision of metal dome arrays remains a key factor in their effectiveness.

As user interface design continues to evolve, metal dome arrays undergo significant transformations to meet the demands of modern electronic devices.

These arrays, featuring dome-shaped metal elements on a circuit board, have witnessed advancements in design that go beyond traditional button layouts. Engineers are experimenting with innovative shapes and configurations to optimize the feel and responsiveness of metal dome arrays.

The incorporation of 3D printing technology allows for intricate designs that were once impractical. This evolution is not merely about functionality but also aesthetics, with metal dome arrays contributing to the visual appeal of electronic interfaces.

From sleek consumer electronics to cutting-edge industrial controls, the evolution of metal dome arrays reflects the dynamic nature of contemporary user interface design.

Metal dome arrays serve as integral components in membrane switches and keypads, contributing significantly to the tactile feedback experienced by users. Tactile feedback is essential in user interfaces, providing a responsive and satisfying feel when pressing buttons. These arrays are designed to withstand repetitive use, ensuring durability and reliability in various electronic devices.

Manufacturers carefully choose the materials for metal dome arrays, often opting for high-quality stainless steel due to its resilience and conductivity. The domes are precisely placed on a circuit board, forming a pattern that corresponds to the layout of buttons on the device. When a user presses a button, the metal dome collapses, making contact with the underlying circuit and completing the electrical connection. This mechanism not only provides tactile feedback but also ensures the electrical integrity of the switch.

The manufacturing process of metal dome arrays involves several intricate steps to achieve precision and consistency. It typically begins with the selection of the base material, where stainless steel is a popular choice. The metal sheets are then treated to enhance their mechanical properties and corrosion resistance.

Next, a specialized tooling process is employed to shape the metal into dome structures. Precision is crucial during this phase to ensure uniformity in the domes' characteristics. The shaped metal domes are then plated to enhance their conductivity and overall performance.

The placement of metal domes on the circuit board is a delicate process that demands accuracy. Automated assembly systems are often utilized to achieve high efficiency and minimize errors. The spacing and orientation of the domes are critical to ensuring proper alignment with the device's buttons.

Quality control measures are implemented throughout the manufacturing process to identify and rectify any deviations from the desired specifications. This includes testing the tactile response, electrical conductivity, and overall durability of the metal dome arrays.

We are a professional manufacturing and design company for membrane switches, metal domes, light guide sheets and die-cutting products, founded in 2009. We have over 14 years of experience in this industry and are based on technology.

It is our pride to have factories and R&D centers that we own hence; we always adhere to the development philosophy of people-oriented, technology, quality first, service first. Our quality control system adheres to ISO9001 and we utilize support equipment that meets international advanced standards.

Provided we keep improving quality, innovation always continuing as well as customer centric approach, our customers will be happy with us and their expectations met well beyond what they had thought

Guozi tablet ,also known as metal dome, are widely used in bank POS machines and cash machine buttons. With an operating force of at least 100gf and a quick rebound upon pressing, these buttons provide a precise and comfortable user experience. We has developed special function Guozi tablet buttons to enhance the accuracy of the button and the surface cover, resulting in an improved customer experience in terms of feel, value, and comfort.

Medical FPC membrane switch is an innovative control interface specially developed for the medical field. This membrane switch uses cutting-edge flexible printed circuit (FPC) technology to ensure unparalleled flexibility and adaptability.Its excellent durability and flexibility ensure reliable and precise control functions of medical equipment. In addition, the FPC structure is easy to clean and disinfect, meeting the stringent hygiene requirements of medical environments.

With their slim profile and tactile feedback, membrane switches offer a sleek and modern aesthetic to complement any vehicle interior. They can be easily integrated into complex electronic systems, providing drivers with intuitive and responsive control of key functions such as climate control, audio, and navigation. Overall, the use of membrane switches in automotive applications helps to enhance safety, convenience, and comfort for drivers and passengers alike.

Metal Dome Arrays provide a responsive touch experience, adding a user-friendly interface to home appliances. Their durability ensures long-lasting performance, contributing to the overall satisfaction of users.

Metal Dome Arrays enhance the efficiency of control panels in industrial equipment by providing precise tactile feedback. Their durability ensures a reliable interface, contributing to the smooth operation of industrial machinery.

Absolutely! We provide customization options for Metal Dome Arrays, allowing you to align the design with your consumer product. Tailor the tactile experience to meet your specific requirements.

Yes, they do! Metal Dome Arrays are compatible with a variety of touch-sensitive interfaces, including automotive displays. Enjoy seamless touch control and durability in consumer electronics, even in automotive applications.

Yes, indeed! Metal Dome Arrays are perfect for portable devices, offering a responsive touch experience. Their durability makes them an ideal choice for consumer electronics with touch-sensitive interfaces.