HONGMAO designs and manufactures high-quality graphic overlays for industrial control panels, medical devices, and consumer electronics. Using UV-resistant inks, durable polycarbonate/polyester substrates, and precision laser cutting, our overlays withstand extreme temperatures (-40°C to 130°C), chemicals, and abrasion. With ISO 9001 certification and 15+ years of expertise, we offer OEM/ODM services, including embossing, selective texturing, and EMI shielding integration. Trust HONGMAO for fast prototyping, UL/REACH compliance, and solutions tailored to aerospace, automotive, and IoT industries.

Our advanced technology graphic overlays integrate technical functionality with modern aesthetics. At Hongmao, we manufacture overlays using advanced materials and printing techniques to meet the high expectations of B2B clients who demand consistency, clarity, and endurance in every component.

Hongmao delivers advanced technology graphic overlays built to meet modern equipment design standards. These overlays are not only functional but also visually refined, ensuring brand consistency and enhanced usability. Our solutions serve various B2B sectors such as medical, industrial, and automotive control systems.

With deep expertise in interface solutions, Hongmao provides chemical etching graphic overlays films with high precision and durability. These overlays withstand repeated usage and harsh chemicals, making them ideal for industrial devices. Our B2B clients value the long lifecycle and professional customizability of every film.

Hongmao’s custom branding graphic overlay service supports your business in creating strong, recognizable user interfaces. We collaborate closely with clients to deliver overlays that reflect brand values while maintaining technical accuracy and durability, ideal for high-performance industrial and commercial environments.

We are a professional manufacturing and design company for membrane switches, metal domes, light guide sheets and die-cutting products, founded in 2009. We have over 14 years of experience in this industry and are based on technology.

It is our pride to have factories and R&D centers that we own hence; we always adhere to the development philosophy of people-oriented, technology, quality first, service first. Our quality control system adheres to ISO9001 and we utilize support equipment that meets international advanced standards.

Provided we keep improving quality, innovation always continuing as well as customer centric approach, our customers will be happy with us and their expectations met well beyond what they had thought

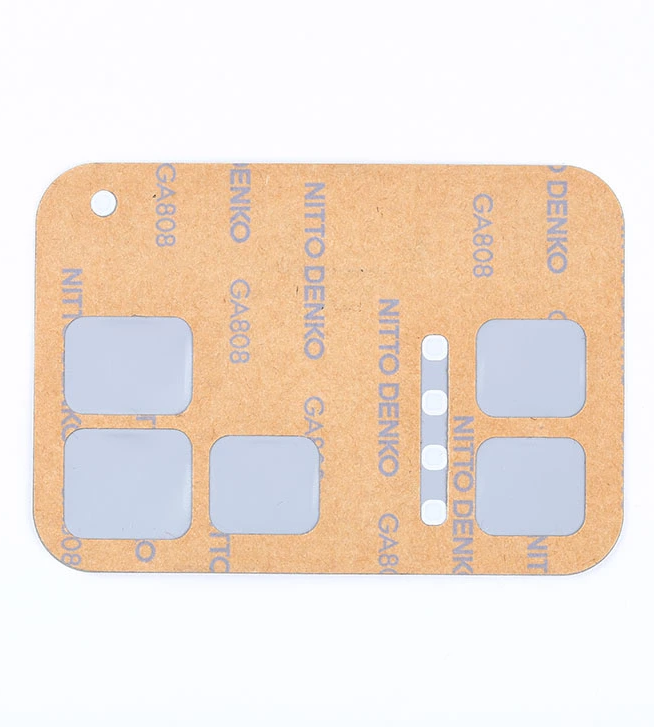

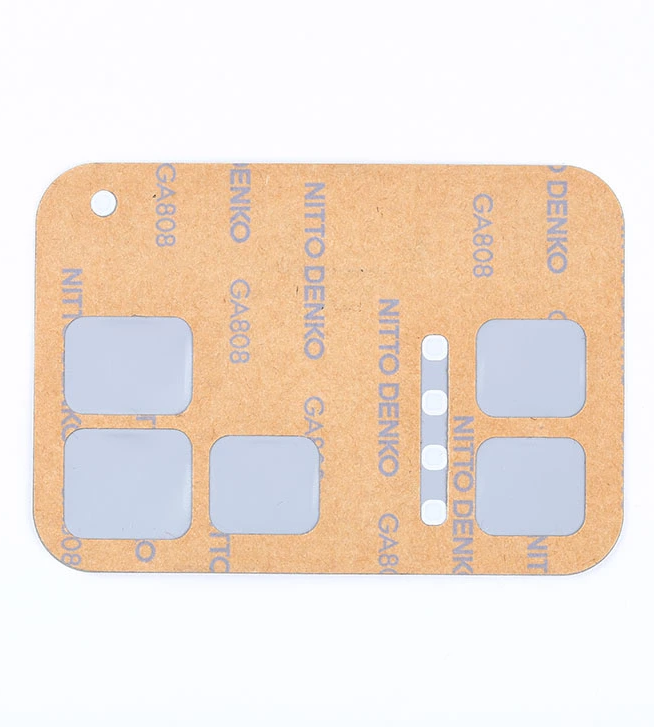

Guozi tablet ,also known as metal dome, are widely used in bank POS machines and cash machine buttons. With an operating force of at least 100gf and a quick rebound upon pressing, these buttons provide a precise and comfortable user experience. We has developed special function Guozi tablet buttons to enhance the accuracy of the button and the surface cover, resulting in an improved customer experience in terms of feel, value, and comfort.

Medical FPC membrane switch is an innovative control interface specially developed for the medical field. This membrane switch uses cutting-edge flexible printed circuit (FPC) technology to ensure unparalleled flexibility and adaptability.Its excellent durability and flexibility ensure reliable and precise control functions of medical equipment. In addition, the FPC structure is easy to clean and disinfect, meeting the stringent hygiene requirements of medical environments.

With their slim profile and tactile feedback, membrane switches offer a sleek and modern aesthetic to complement any vehicle interior. They can be easily integrated into complex electronic systems, providing drivers with intuitive and responsive control of key functions such as climate control, audio, and navigation. Overall, the use of membrane switches in automotive applications helps to enhance safety, convenience, and comfort for drivers and passengers alike.

A: We use polycarbonate, polyester, or PET films with UV-resistant inks and 3M adhesives for durability in harsh conditions.

A: Yes, we tailor overlays with features like EMI shielding, anti-microbial coatings, or IP67 sealing for medical, automotive, and industrial applications.

A: All overlays meet ISO, UL, REACH, and RoHS standards. Documentation is provided upon request.

A: Prototypes are delivered within 5–7 days after design approval.

A: Yes, we integrate LED/EL backlighting and transparent zones for display visibility.

A: Our ISO-certified facility conducts batch testing for adhesion, thermal resistance, and lifespan (1M+ cycles).